wonderings

Well-known member

We had a problem with a job we were imprinting on. The stock is a 14pt Carolina coated 2 side. We could never get the colour or shine that customer wants on our Versant 2100 so we did what we have done in the past, printed shells on press and imprint the black text digitally.

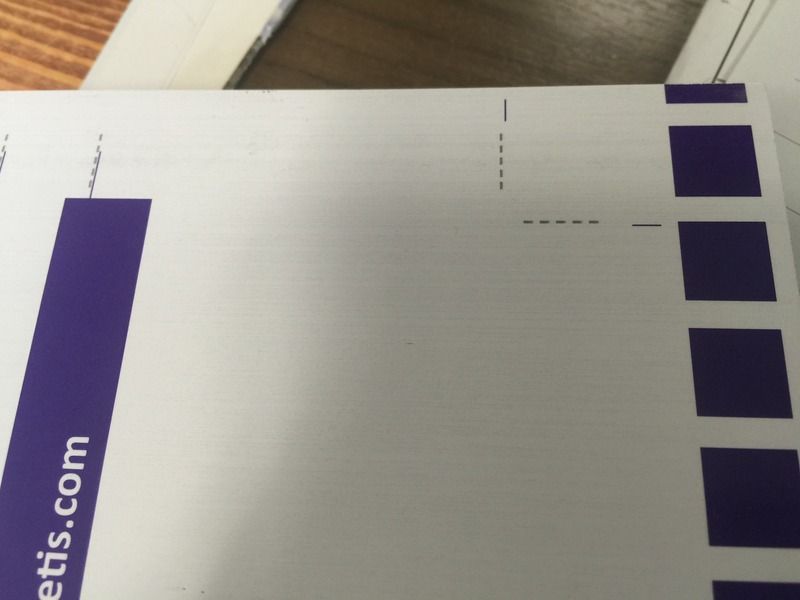

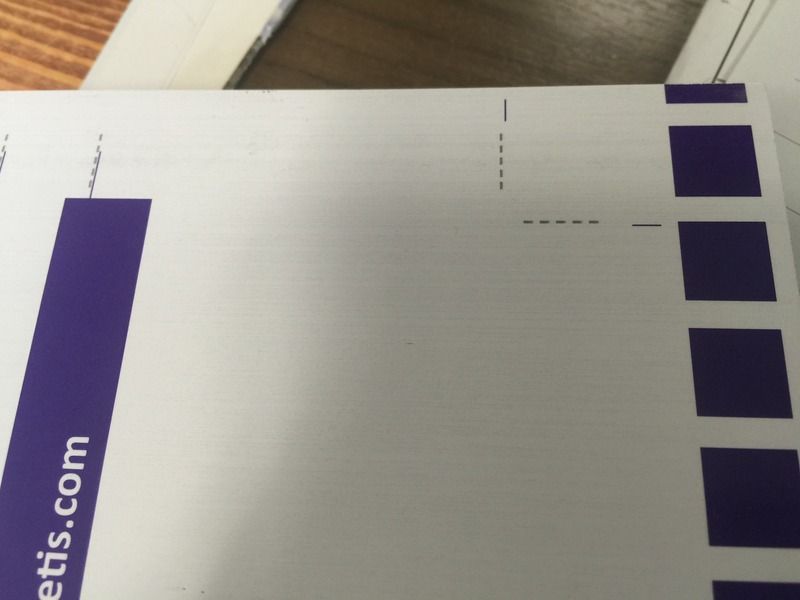

So the problem came up a few days ago when running a job, we were getting black streaks, small, almost like brush strokes, on the job. I tried cleaning anything I could and even replaced the colour drums to rule those out. Problem persisted so I called in service. I was told the problem was being caused by this pre printed stock running through our Versant.

We don't do this a whole lot, usually little jobs that equal a press run off about 15 sheets or so. The part in question was replaced in March for another reason (new parts upgrade). So really since March I would say we have run less the 100 sheets of pre printed stock through our machine. I am being told that these pre printed sheets are causing the problem. We use the least amount of powder we can on the press when running these shells (Komori Spica 29P). I am not against the premise that these are the problem, it just seems strange that so few sheets could cause such a problem, especially since we have been doing this for a long time on various machines, DC260, J75 and now Versant 2100.

Would love to hear thoughts from people doing similar. Have you had any issues running pre printed media through your Versant 2100 or like machine?

So the problem came up a few days ago when running a job, we were getting black streaks, small, almost like brush strokes, on the job. I tried cleaning anything I could and even replaced the colour drums to rule those out. Problem persisted so I called in service. I was told the problem was being caused by this pre printed stock running through our Versant.

We don't do this a whole lot, usually little jobs that equal a press run off about 15 sheets or so. The part in question was replaced in March for another reason (new parts upgrade). So really since March I would say we have run less the 100 sheets of pre printed stock through our machine. I am being told that these pre printed sheets are causing the problem. We use the least amount of powder we can on the press when running these shells (Komori Spica 29P). I am not against the premise that these are the problem, it just seems strange that so few sheets could cause such a problem, especially since we have been doing this for a long time on various machines, DC260, J75 and now Versant 2100.

Would love to hear thoughts from people doing similar. Have you had any issues running pre printed media through your Versant 2100 or like machine?