We have an Azura C125 rinse gum unit (processor) that is about 4 years old now and we're having a couple problems with it.

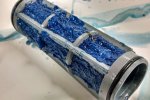

First issue is that Agfa changed the chemistry of the TS Gum a while back and since then we're getting a thick blue sludge in our system that is a real hassle to deal with. The filter needs to be cleaned daily (depending on use) otherwise the sludge builds up on it (see photo). I've contacted our Agfa reps and at first they had never heard of this issue, but after repeated contacts they must have escalated the problem and they came back and said they have a cleaning solution called Azura Oxy Cleaner. I'm still trying to find out what it is. They gave me a price for this stuff $283.50! Judging from the description it might be 16 bottles of the stuff, I'm still waiting to hear if it is. I'm not ordering it if it is 1 bottle.

The second issue is that the plates are not coming out cleaned up. There is some of the rinse/gum chemical on the tail edge of the plates so when the stack up the stuff gets in between the plates and they stick together. Once the pressmen pull the plates apart the image is weakened and doesn't hold ink then we have to remake the plate. We're going to start slip sheeting the plates now to try and eliminate that problem.

Also, it seems as if the TS Gum isn't lasting as long now that the chemistry has changed. It start to have a funky smell after about 150 square meters and we have to change it.

We've cleaned the rinse gum unit thoroughly, swapped rollers and still are having this problem. I'm pretty sure we need new rollers.

Has anyone used the Azura Oxy Cleaner? How well did it work?

Has anyone had problems with plates not cleaning up coming out of the rinse gum unit? Did you find a solution to the problem?

Thanks for any input.

First issue is that Agfa changed the chemistry of the TS Gum a while back and since then we're getting a thick blue sludge in our system that is a real hassle to deal with. The filter needs to be cleaned daily (depending on use) otherwise the sludge builds up on it (see photo). I've contacted our Agfa reps and at first they had never heard of this issue, but after repeated contacts they must have escalated the problem and they came back and said they have a cleaning solution called Azura Oxy Cleaner. I'm still trying to find out what it is. They gave me a price for this stuff $283.50! Judging from the description it might be 16 bottles of the stuff, I'm still waiting to hear if it is. I'm not ordering it if it is 1 bottle.

The second issue is that the plates are not coming out cleaned up. There is some of the rinse/gum chemical on the tail edge of the plates so when the stack up the stuff gets in between the plates and they stick together. Once the pressmen pull the plates apart the image is weakened and doesn't hold ink then we have to remake the plate. We're going to start slip sheeting the plates now to try and eliminate that problem.

Also, it seems as if the TS Gum isn't lasting as long now that the chemistry has changed. It start to have a funky smell after about 150 square meters and we have to change it.

We've cleaned the rinse gum unit thoroughly, swapped rollers and still are having this problem. I'm pretty sure we need new rollers.

Has anyone used the Azura Oxy Cleaner? How well did it work?

Has anyone had problems with plates not cleaning up coming out of the rinse gum unit? Did you find a solution to the problem?

Thanks for any input.