Thank you, Stephen.

Asures,

You're spending a lot of time here trying to pound a square peg into a round hole. Large format inkjet printing isn't lithography, and the same rules and processes just don't apply.

For instance: "Trap" is a term used in lithography, but it doesn't have any real meaning in inkjet. In litho, you have individual printing units laying down all the dots for a given part of an image in just the area where the blanket is in contact with the sheet, and as the sheet passes unit to unit, it's worthwhile to think oh how each ink reacts to and is affected by the others on the sheet as trap, since the already-down colors are in a sense 'trapping' the next ones down. But no such thing happens in inkjet. True, the inks interact, but they do in such different ways that to think of the process as 'trap' is going to lead you off chasing any number of wild geese.

Next thing to note is that most print buyers in the movie industry and at high-end design firms doing national campaigns are far from printing experts. If they care about G7 at all, it's because someone came in and sold them on it.

Don't believe me? The next one that tells you anything about G7, ask them what it even means, and why they want it. I absolutely positively guarantee you and blank look and a stuttering response.

Also, I can tell you that all I do for a living is color workflow management for large and grand format printers, that I've been doing it for over ten years, and that I have literally traveled around the world doing it.

And in all that time, I have never once ever made a device-link profile. And the reason is because they serve no purpose in this industry.

Now, what I can tell you is that if you're really serious about color, you're handicapped a little by the 360, but not for the reasons you list. The reasons are that the machine suffers from some real color inconsistency issues, and also that HP made the decision when they released the machine to make it a "contone-only" printer, which means that a lot of the inking controls that should be available when making profiles for it are not, and you're left with just the pretty rudimentary controls left to you by HP.

Also of note is that the onboard ICC profile-making engine pretty much sucks.

However, given what you've got to work with, and as Pauly said, the way it works in this industry is that if you're going to emulate one machine with another machine, the first thing you need is dead-on accurate profiles of both machines.

We'll assume your Gracol profile is accurate, so then what you need is an accurate profile of your machine in your environment printing on the material you're using.

Not necessarily such an easy thing to make, but once you have it, then you convert your image to the profile of the device you wish to emulate, and you print it to the device profile of the device you're using.

That's how it works. That's how it's done. And that's the only effective way to do it. And the bottom line is that if you do everything correctly, you'll get a match, with two caveats: White point of the media and gamut of the device.

See, in this industry there are no common white points and no ISO standard CMYK values. Also the selection of media are much more vast.

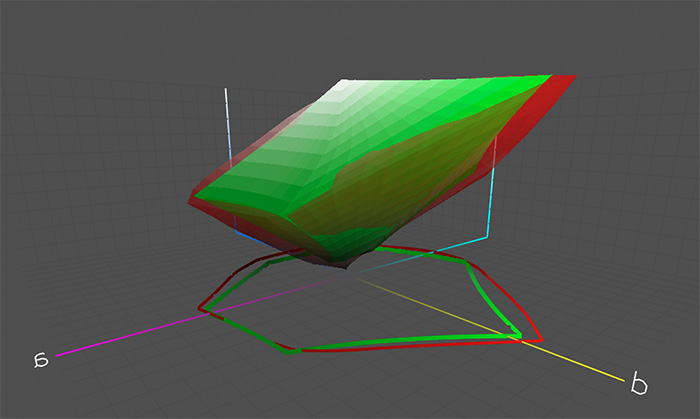

So, all that in mind, here's the gamut of an HP360 run by ONYX Thrive printing on 3M IJ180C; settings were 120 10 pass. It's superimposed over the gamut of Gracol2013. The red is the HP, the green is Gracol. As you can see, the HP doesn't quite cover all the red of the Gracol space, but the difference sure isn't any 12 delta E; it might be two at most. So note also that other than white point, other than that very slight area of red, the HP will cover every bit of Gracol, which means that profiled and set up correctly, you can basically expect out of this machine and on this media a perfect match, with the usual white point exceptions. (My guess is also I'm sure that with full control I could get it out there -- but as the machine is now, that's baked into the cake.)

Bottom line: Forget G7 in large format inkjet printing. It serves no purpose at all.

Mike Adams

Correct Color