prepressdork

Well-known member

Hi all,

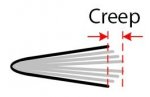

I was wondering if anyone can provide any guidelines they use for determining if a job should be shingled?

Thanks,

pd

I was wondering if anyone can provide any guidelines they use for determining if a job should be shingled?

Thanks,

pd