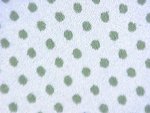

We are experimenting a problem with the dots on Kodak Thermal Direct plates, we have compared them with our previous plates from Kodak, the Sword plates, and we see that the formation of dots do not have a round figure but a broken dot and this, when we print, gives us a snowflake look on the prited sheet. We would appreciate very much if someone has had this kind of problems with Processless Kodak Thermal Direct plates? We have checked out our CTP and M1000 press and we find these sttings are within the adequate settings. We would appreciate any help you can give us.

Thank you.

Regards,

Francisco Alvarado

Thank you.

Regards,

Francisco Alvarado