imattination

New member

Hi there, we have a Xerox Versant 2100 which we are struggling to diagnose an ongoing fault with.

We have replaced the Fuser with a brand new Unit and are still getting the same issues and faults.

It often throws up error code: 099-339, 099-335, 099-399.

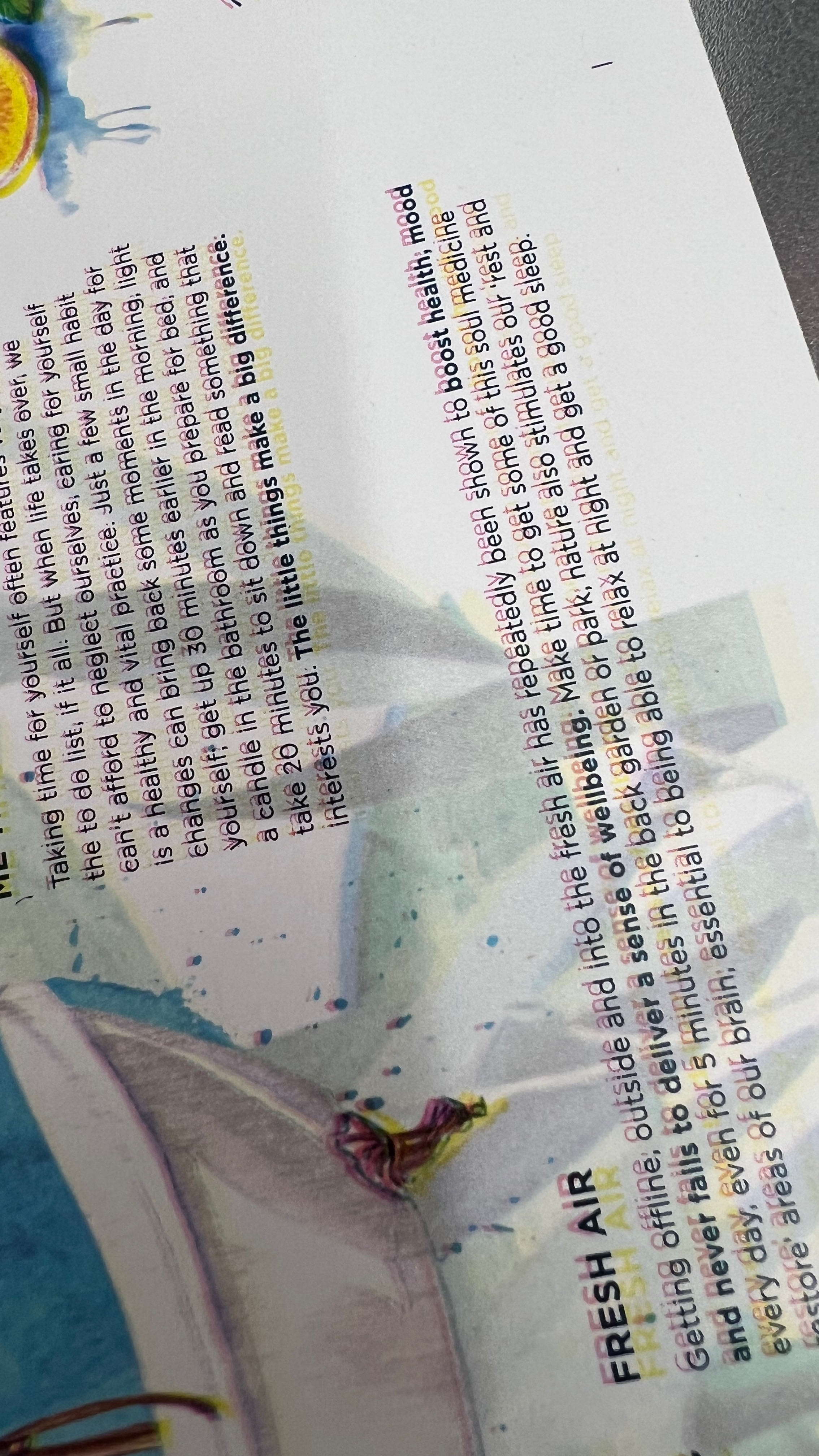

We manage to print one single sheet through, the second print them comes out as below (blurry) and the third worse until we get to the fourth where the machine then jams and throws up the error code.

The fuser belt often walks out of line - however the fuser has been replaced with a complete new unit and still walks out of line.

We replaced the Pressure Roller only at the start of the year and has not done a huge amount of prints so wouldn't understand why this would have suddenly gone.

Hoping someone has experienced similar and can help.

We have replaced the Fuser with a brand new Unit and are still getting the same issues and faults.

It often throws up error code: 099-339, 099-335, 099-399.

We manage to print one single sheet through, the second print them comes out as below (blurry) and the third worse until we get to the fourth where the machine then jams and throws up the error code.

The fuser belt often walks out of line - however the fuser has been replaced with a complete new unit and still walks out of line.

We replaced the Pressure Roller only at the start of the year and has not done a huge amount of prints so wouldn't understand why this would have suddenly gone.

Hoping someone has experienced similar and can help.