Ok, now I am totally confused, I read the blogspot but I need it dumbed down a bit. If I have a press that is giving me a constant TVI of +25% in the halftones (50% gives 75% on sheet) and I want to bring it down to 18%, or a 50% that gives me 68% on sheet, why not have a compensation to bring the 50% tone on plate down by 7%?

Assuming the press is stable of course.

The method described on my blog is pretty much standard and used by most vendors' TVI compensating software although the terminology might be different and it may be a two curve workflow vs one. Simply adding or subtracting % will not give you the correct required tone values.

Let's say that when we ask for a 50% in the native file we want to measure the result in the presswork as 68% (18% dot gain/TVI)

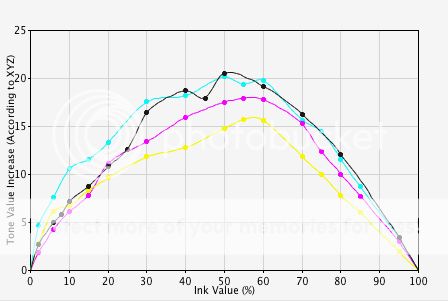

In the chart on the blog a 50% tone request in the file resulted in a target 68% tone in the presswork.

But in the new presswork the 50% file request results in 90%

If we did it your way we would subtract 50% from 90% and then subtract that difference from 50% and then map 50% to 10% (90% - 50% = 40%, 50% - 40% = 10% ). But a 10% request in the file isn't going to deliver your target 18% dot gain at a file requested 50%.

On the other hand, looking at that same target 68% you can see that it was delivered in the new presswork from a requested tone value of 30%. So a 50% request in the file needs to be mapped to a 30% tone request. This 30% file request will result in the 50% request in the file delivering a 68% in the presswork which is what the target is.

This all sounds complicated when you read it, but it's very simple once you understand it.

Basically you need:

1 - a target tone (the tone you want to match)

2 - a tone request (the tone specified in the source file (PShop, InDesign etc.)

3 - a press response (the tone that you actually got in the presswork).

With those three elements the software, or you manually (as per the diagram in the post), can create a compensating curve that is applied to plate imaging.

Note that the halftone dot value that's on the plate is NOT involved in the calculation. It's not involved because it is not needed to create the plate curve. All that's required is that the plate imaging is consistent.

This is a one curve workflow. And unless there is a specific need, this is the preferred method.

In a two curve workflow, a curve is applied to the plate to make it linear, then the same 1, 2, 3 steps above are used to create the compensation curve.