hi mr. gardo

Thanks 4 ur detailed reply. suppose i didn't leniarized, if 50% in file comes 73% on plate, how much we need to compensate? pl explain me

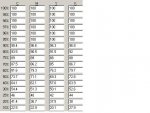

To build a compensation curve you need:

1- Original % requests - that is the 10% 20% 30% etc. in the original file (illustrator, PDF, InDesign etc.)

2 - A target - that is the % values you want on press at each % in the original file (e.g. for a 50% request in the original file you want to measure 70% on the press sheet)

3 - A press run at your correct solid ink densities in order to measure what tone value you actually get at that requested tone. (e.g. I asked for 50%, my target was 70% but I measured 75% on the press sheet.

From those three pieces of information (requested tone, target tone, and press tone response) you can easily build a compensation to make the 50% request measure 70% on the press sheet.

Note - I did not mention what the tone values on the plate are. That's because it doesn't matter what the plate tone values are. All that matters is that whatever they are they are consistent. That means (assuming that the plate imaging is correctly set up by your vendor) that if I ask for 50% in my file and I get 42% on the plate then every time I ask for 50% I should get the same 42% tone on plate.

Note - I did not mention dot gain values. Dot gain values are variables as they change with screening and density. They are not targets. The target is the tone response that you want on the press sheet. The tone value is an absolute.

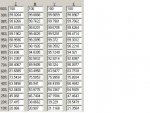

I did take the numbers you provided and plotted them to see how well the CMYK curves relate to one another. I'm assuming that you are running to standard newsprint densities and I'm assuming that the press run was good and that you're measuring was correct. If you look at the curves plotted out:

You'll notice that the Yellow and Black have some strange waves in them. That usually suggests a problem that should be investigated before you try to build any compensation curves. If there is a problem and you try to fix it with curves then you will just make the problem worse. I would not build any curves until I had investigated why your press curves have such strange shapes and then fixed the problem.

best, gordon p