Ynot_UK

Well-known member

Does anyone have any thoughts on this?

The stock is standard self adhesive office grade laser labels, fed face up from Tray 4 on the PF-706 deck and output face up on the FS-532 for the straightest path.

The scenario is as below and happens regularly with this repeat job.

I'm aware the CED mentions the machine does not officially support label stock, however in practice I would imagine it supports them no more or less than the KM office grade machines (454e / 554e) which we have successfully run labels on for years, before getting the Pro951. One issue we used to have when running labels on the 554e was fluid seepage and curling, because of the higher fuser temperature. The Pro951 fixes that issue. If we can fix the intermittent problem of the corners catching on whatever and creasing, the job would be perfect - the image quality is great and the stacking spot on.

The stock is standard self adhesive office grade laser labels, fed face up from Tray 4 on the PF-706 deck and output face up on the FS-532 for the straightest path.

The scenario is as below and happens regularly with this repeat job.

- Requested 10 sets offset (job saved in a Public Box)

- Circa copy #585 I pressed the FS-532 pause button to take off sets 1-6 to start boxing up

- Pause correctly initiated after #600

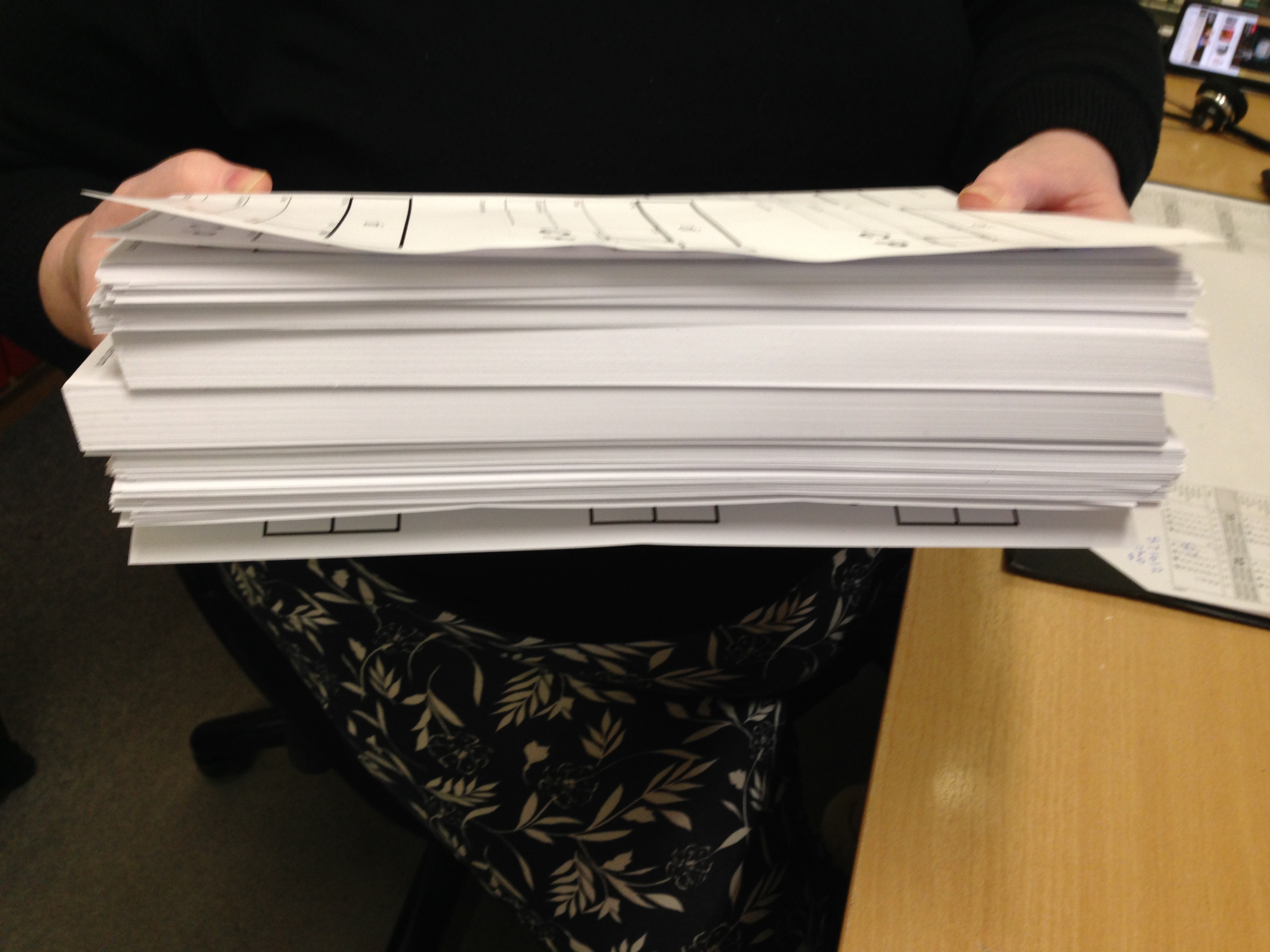

- Sets 1-6 taken off the FS-532 (all stacked perfect with no corner creasing)

- Job resumed at FS-532

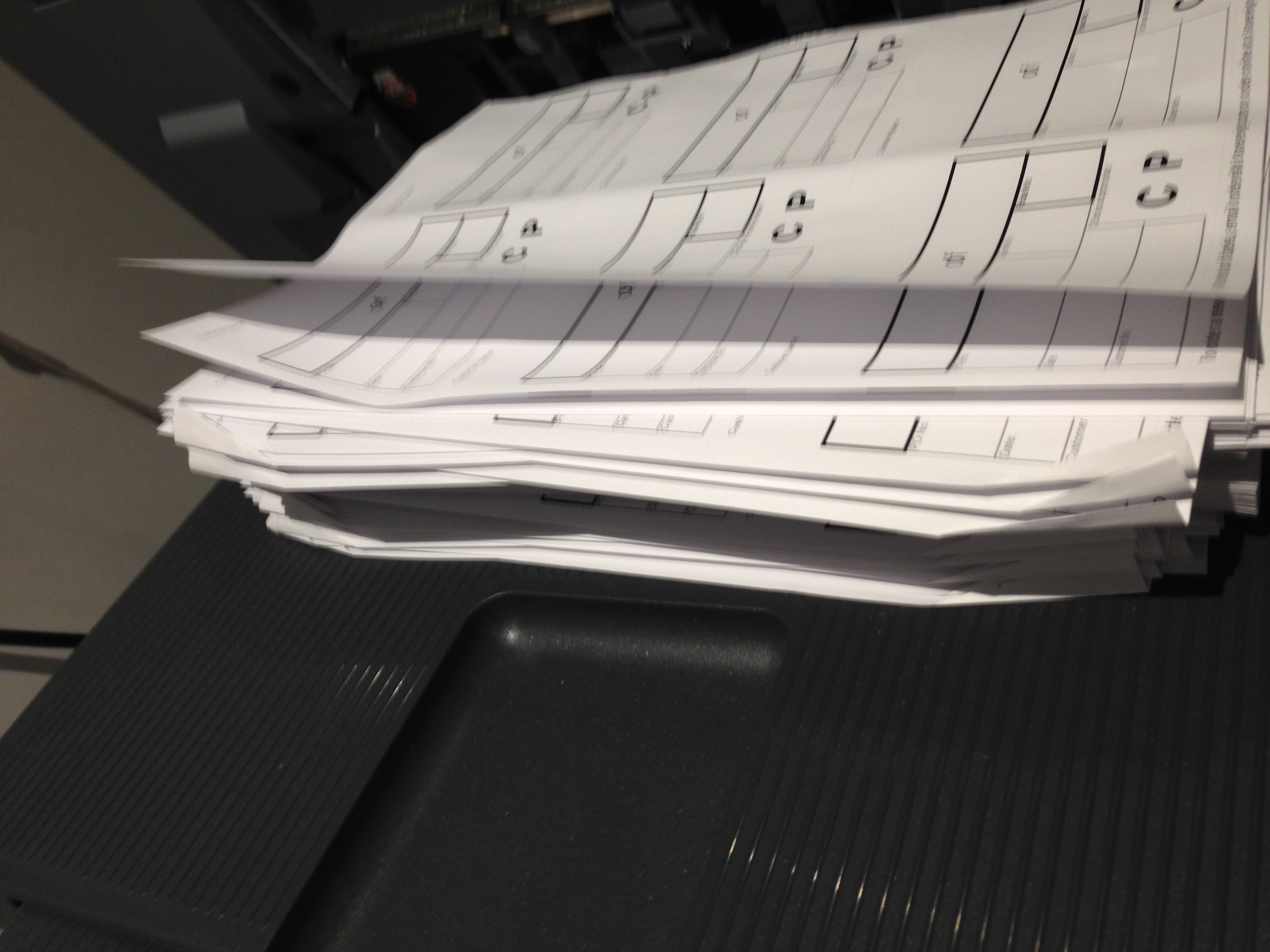

- The photos are of the remaining four sets

- Set 7 was messy

- Set 8 was perfect

- Set 9 was good, except for two copies

- Set 10 was messy

- There were no jams experienced throughout the job

I'm aware the CED mentions the machine does not officially support label stock, however in practice I would imagine it supports them no more or less than the KM office grade machines (454e / 554e) which we have successfully run labels on for years, before getting the Pro951. One issue we used to have when running labels on the 554e was fluid seepage and curling, because of the higher fuser temperature. The Pro951 fixes that issue. If we can fix the intermittent problem of the corners catching on whatever and creasing, the job would be perfect - the image quality is great and the stacking spot on.

Last edited: