My name is Keith and I'm an avid Morning Flight user . . . I don't see Morning Flight as an estimating program, but more like a flight recorder.

Appreciate the ringing endorsement, Keith. Don't see Morning Flight as an estimating program?!? You had me going there for a minute. The answer came a few sentences down: “I do the pricing, and the program does the calculating.” Couldn’t have asked for a better definition of the role an estimating system should play in the print shop.

Pricing is, and always needs to be, a cornerstone of a company’s marketing strategy.

Estimating should be looked at merely as the mechanical means of applying that strategy, using a predetermined set of pricing factors. In other words, find out how much you can afford to charge (the customer’s tipping point, based on your value proposition of quality, service, price), then synchronize your estimating program with it.

In the Morning Flight manual, I caution our users to not let the software dictate pricing:

“Some estimating systems claim to know your market's sweet spot, the exact point at which your prices are low enough to keep and attract customers, yet still high enough to earn you a profit. Their manufacturers suggest you use these miracle systems straight out of the box, abandon the prices your customers have gotten used to, and step boldly into a more lucrative unknown. What works in Brooklyn, they say, will work in every state and hamlet in the country. There's a bridge in Brooklyn you may want to keep an eye on, because what you'll be stepping into is not where, under the rosiest of circumstances, I would want to take bold steps.”

Ok, so I don’t suggest to our users that they keep a set of Franklin Estimating books on their shelf for reference as Keith does. But frankly, Keith, you could do worse. Franklin has been around literally forever, and they still produce what I consider the gold standard for “average U.S. rates.” NAQP publishes an annual Printing Industries Pricing Study that’s less comprehensive but can be put to good use when you need a second opinion (

PrintImage International: News).

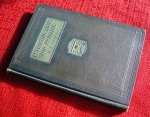

Wouldn't be right if I didn't confess that I, too, keep a little Franklin book on my shelf. Titled “Estimating Hints for Printing” and written by by R.T. Porte, it’s not a Franklin book per se, having preceded the Franklin Printing Catalog by some years.

For those of you who have ink running through your veins, Roy Trewin Porte was born in 1876. His love of press work came to him as a child when he prepared small printing jobs on a hand press in his mother's home. He became a printer and editor of various papers. In 1916, he moved his family to Salt Lake City, Utah, to assume the position of secretary of the Ben Franklin Club. He published the first edition of the Price List which became well-known as The Franklin Printing Catalog. In 1924, Porte established the Porte Publishing Company to continue publishing the catalog.

Interesting observation from Chapter 1:

“The cost system was at first hailed as the corrector of all such evils, but it was soon discovered that results from cost systems varied twenty-five percent on the same work when reproduced at intervals in the same office.”

So much for the validity of BHRs. Remember, this was written in 1919, before any of us ever laid eyes on a printing press. Porte travelled widely throughout the West to collect price data for his Franklin Printing Catalog. His message was simple: Don't charge what it costs you to print a job, but charge what other printers are charging for the same "class" of work, then try to produce the job at lower cost. That's pretty much the premise of any pricing guide to this day.

And no, I didn’t buy the book

new.

Hal Heindel

http://www.morningflighthelp.com