Hi,

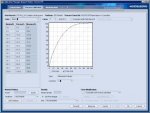

huge dotgain distortion on press. Dotgain curve on fingerprints cd-74-6 UV linear plate 50%-50% , print 50%-90,9%.(picture)

Not much left raster from 50%-100%.

Should drop dotgain on some normal value and do it color correction with icc cmyk converter?

Any solution?

Thanks

huge dotgain distortion on press. Dotgain curve on fingerprints cd-74-6 UV linear plate 50%-50% , print 50%-90,9%.(picture)

Not much left raster from 50%-100%.

Should drop dotgain on some normal value and do it color correction with icc cmyk converter?

Any solution?

Thanks