Terry,

But you act like I had a friggin' choice. Yeah, I coulda quit. I sure as hell felt like it because it was NOT my responsibility to get my company on board and even get the pressman and everyone here on board. If I could have afforded to hire a G7 Expert myself and get it over with, I would have. I had no such luxury.

I Spent. Not my boss. Me. They paid me the same as they would have no matter what. Yeah, they may have put a half-day on all 6 press runs together. Not a big deal to them if they have the time and already made sure the machine was checked and brought into great working condition (new blankets, etc., etc.). They saved money, and if you say they didn't, I can't even believe how you could justify that.

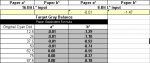

Who paid? Me. Who spent hours? Me. Do I have knowledge now that I wouldn't have before? Yes. Is it a total loss or waste of time? No. Will I need the calculator again? No. Just like I wouldn't need IDEAlink Curve 2 or an Expert after it's set up right. But if I do, it's easy-cheesy to do it again. Much easier than the first because I've already done it. And this time, it'll take one press run - if that. If our solids are within tolerance of new specification that may come, I might be able to do it without a press run (since I have all the numbers already from the calibration run, and would just choose a new source to aim to, plug in some numbers for the new solid and overprint aims, and my calculator gives me paper-dependent corrected solids aims, and if I'm in tolerance still there, then I have paper-dependent gray balance numbers I'm aiming to, may have to, in PhotoShop with new specification profile, Absolute Colorimetric Intent, use 6 patches on P2P25 target, 1 patch on GrayBalance target, to get 16-bit L* (and a* and b* on GrayBalance target), which when plugged into my calculator, converts to 8-bit L*, then to density, subtracts paper, and gives me the density aim values for my CMY gray patches, a* and b* converted to 8-bit, moves for M and Y given, and my calculator spits out changes to K,C,M, and Y plate curves needed, and I'm done in no time).

For a person that has time on their hands because I sit here almost all day every day with almost nothing to do and get paid for it, I don't mind doing it really. What else would I do? Actually, my boss has even let me work on my other business while I've been here not having much to do after I got done with GRACoL study years ago (until this year), and in the mean time, I've been working on my own thing when jobs are not in here. How many places would allow that? So on one hand, I want more freedom. On the other, I already have more than most. I just have to sit in a building where I'd rather be in a location I want, with location freedom and time freedom. So I work towards it when I can.

But me having gotten it done finally puts it behind me and we have verifiable quality control and aiming to an ISO standard on coated paper - per the method G7 for press calibration - per the specification GRACoL 7 - via the official ICC profile GRACoL2006_Coated1v2. As far as uncoated, we're as up-to-date as the beta in the U.S. is, and within tolerances of it.

So there's really nothing anyone should say negative about it, or act as if one doesn't go about it just the way that's recommended, that it's no good. I actually did go by all the math (then some) and automated the manual method. So I still did the manual method, just I can repeat it much faster and do it faster than the manual method. The paper is out of spec because of optical brighteners (lower than ISO standard paper -b) on coated and uncoated. But everything else is in spec.

I can now put this chapter of my life behind me and concentrate on what I consider my next objective/goal I have been working on for about 2.5 years.

This is what you and others may not understand about small business. They've been taken enough over the years, and the margins are tight enough, that something has to be proven to them basically before they will decide to do it, and then they still may not do it for years. They have to see the benefit. And my boss is no different than any other. If you have an employee that looks like they can do something, and look to mostly know what they're talking about, would you spent the thousands extra, or give the guy a chance to prove it to you. I guess my boss wanted me to prove it to them without all the extra money being spent. We already spent a good amount on an ongoing basis, and like I said before, even when we were out of spec, our printing still looked close. Now it's indistinguishable from the Certified Kodak MPI GRACoL proof that we proof.

Maybe my boss is different and extra hard to get on board. But I doubt where I work is that much different than most small businesses where they make due with what they can. And I guess they think how my saying goes: An expert can do for $0.10 what anyone can do for $1. As far as real money spent, I proved that, and got an education in more than G7.

In time and effort spent, I guess it depends on how people look at it. I've spent 2.5 years on something (nothing to do with printing or color management) that if it doesn't pay off, I've never gained much money from it yet, and some would consider I wasted 2.5 years of my life. But if it does pay off, I could possibly, by the Lord's grace, be a millionaire or even multi-millionaire within a year, and never have to work a day again in my life unless led by the Lord to do so, since He will be my only Master. I know what's possible. Have I achieved it yet? No. But I work towards it as if inevitable. Let's say I'm a much better Excel user and MQL4 programmer than I was a couple years ago, and I don't mind putting in the effort to get to a goal, as you see.

I hope you continued success in whatever you endeavor,

Regards,

Don

Don, I'm not trying to be a jerk about this and I (mostly) applaud your efforts. All I'm really saying is look at the amount of time and effort you've put into this over the past couple of years. Maybe you did it all on your own time or maybe not, but I guarantee the way you went about it was WAY more expensive in the long-run than hiring an expert in the first place.

Regards,

Terry