Bill W

Well-known member

Greetings,

I have run a few profile runs on presses in our Texas plant. The last run produced a strange looking profile. Until this last run I have been using a custom chart with 992 patches - I am a narrow web flexo printer and "regular" charts do not fit on my press web. This last run I built a reduced IT8.7-4 which fits on my web, but unfortunately can only be read in patch mode using an iO.

The IT8.7-4 chart I used to reduce also had the P2P with it. I built two reference files from the chart so I could scan them separately, for testing purposes. While the 2 new references files, I made, in some places have values such as 69.9%, where the original had a value 70%, I felt that they represented the IT8.7-4 and the P2P properly.

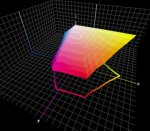

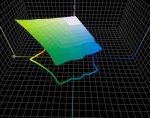

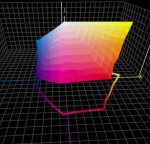

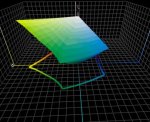

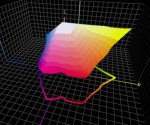

The profiles I made from the last run using the reduced IT8.7-4 are not as smooth as the previous profiles made from my 992 chart. I have attached two screen shots of each, labeled Good Profile 1, Good Profile 2, (from 992 chart), and Bad Profile 1 and Bad Profile 2 (from the reduced IT8.-4 chart).

Anyone have a clue as to why Bad Profile looks like it does. Not only does it have a strange gamut projection, but it also appears to have some strange dips in the lines between values as the color goes from dark to light.

The only thing we have changed between the two runs represented here, besides the chart, is the anilox rollers. They are brand new and not much different in configuration from the ones used on the first run.

-Bill-

I have run a few profile runs on presses in our Texas plant. The last run produced a strange looking profile. Until this last run I have been using a custom chart with 992 patches - I am a narrow web flexo printer and "regular" charts do not fit on my press web. This last run I built a reduced IT8.7-4 which fits on my web, but unfortunately can only be read in patch mode using an iO.

The IT8.7-4 chart I used to reduce also had the P2P with it. I built two reference files from the chart so I could scan them separately, for testing purposes. While the 2 new references files, I made, in some places have values such as 69.9%, where the original had a value 70%, I felt that they represented the IT8.7-4 and the P2P properly.

The profiles I made from the last run using the reduced IT8.7-4 are not as smooth as the previous profiles made from my 992 chart. I have attached two screen shots of each, labeled Good Profile 1, Good Profile 2, (from 992 chart), and Bad Profile 1 and Bad Profile 2 (from the reduced IT8.-4 chart).

Anyone have a clue as to why Bad Profile looks like it does. Not only does it have a strange gamut projection, but it also appears to have some strange dips in the lines between values as the color goes from dark to light.

The only thing we have changed between the two runs represented here, besides the chart, is the anilox rollers. They are brand new and not much different in configuration from the ones used on the first run.

-Bill-