FlightDeck

Active member

Hi all,

I searched the manual and the threads here and not coming up with much info on the internal cleaning of my 24" z3100. I recently began getting dark ink gobs/streaks on the top edges and backs of some prints. The bottom of the MK-R printhead was found covered with ink gunk (with a small amount of it hardened), as was the area around it in the printhead carriage. On the other end of the carriage, the E-G printhead also had some gunk on and around it, just not as much. I manually cleaned these two printheads, haven't yet checked the rest.

I also found some ink gobs on one of the rollers, on a couple of ribs and black foam on the platen(?), and on the paper output tray (I cleaned all of these off).

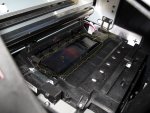

Under where the printhead carriage "parks" I see some kind of pad covered in ink (see photos), with a buildup of gunk on the far righthand edge. I'm not sure how much of this is normal.

The printer is limited home use only, with just over 300 sq ft printed. I assume the light use (long idle times) are actually part of the problem, and I should exercise the printer more often.

Also shown in the photos are lots of white/grey bits of debris. These were mentioned in another thread of mine a couple years ago (http://printplanet.com/forums/wide-format-inkjet-discussion/20862-debris-hp-z3100-prints), as they have plagued me since day one. It appears that the printer somehow makes this debris. It doesn't appear to be paper. More like bits of dried glue? At least now I can see them inside and can vacuum them out, but it would sure be nice to prevent them in the first place, they have ruined far too many prints.

Thanks and regards,

I searched the manual and the threads here and not coming up with much info on the internal cleaning of my 24" z3100. I recently began getting dark ink gobs/streaks on the top edges and backs of some prints. The bottom of the MK-R printhead was found covered with ink gunk (with a small amount of it hardened), as was the area around it in the printhead carriage. On the other end of the carriage, the E-G printhead also had some gunk on and around it, just not as much. I manually cleaned these two printheads, haven't yet checked the rest.

I also found some ink gobs on one of the rollers, on a couple of ribs and black foam on the platen(?), and on the paper output tray (I cleaned all of these off).

Under where the printhead carriage "parks" I see some kind of pad covered in ink (see photos), with a buildup of gunk on the far righthand edge. I'm not sure how much of this is normal.

The printer is limited home use only, with just over 300 sq ft printed. I assume the light use (long idle times) are actually part of the problem, and I should exercise the printer more often.

- How can I remove the printhead carriage so that I can clean the underside more effectively?

- Does anything in the area around the printhead carriage's parking spot require cleaning? It looks nasty...

- What can I do to reduce the accumulation of ink gunk around the printheads?

Also shown in the photos are lots of white/grey bits of debris. These were mentioned in another thread of mine a couple years ago (http://printplanet.com/forums/wide-format-inkjet-discussion/20862-debris-hp-z3100-prints), as they have plagued me since day one. It appears that the printer somehow makes this debris. It doesn't appear to be paper. More like bits of dried glue? At least now I can see them inside and can vacuum them out, but it would sure be nice to prevent them in the first place, they have ruined far too many prints.

Thanks and regards,