DeltaE

Well-known member

Hello Experts,

I am not sure this post suitable here or in color management area, please move it to correct area if needs!

I have to measure a color sample which is printed a spot color - standard L*a*b = (48.6, -0.50, -2.16) after matt-film lamination.

Measuring condition is D50/10 and M3 (with Polarized filter). My device is a eXact Standard with M3.

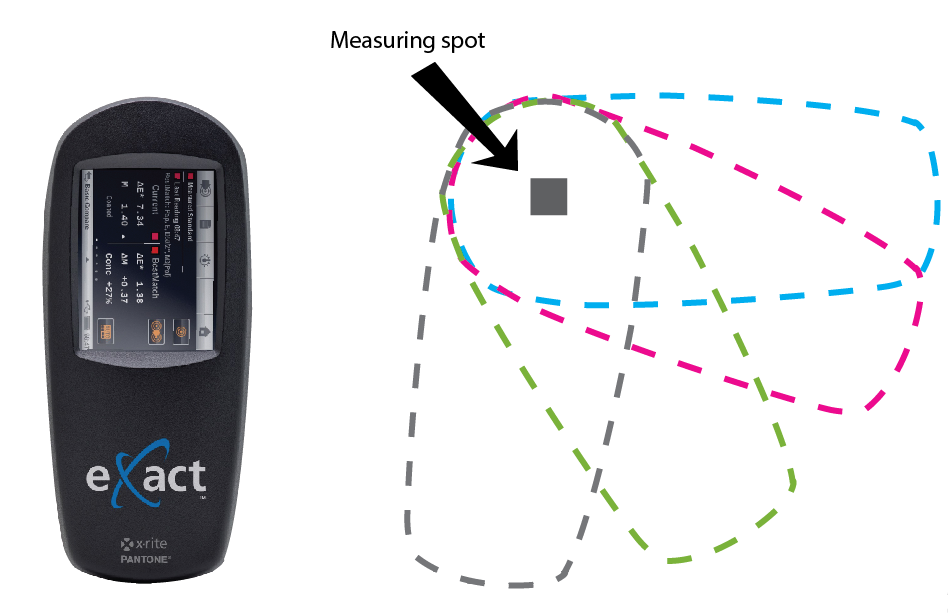

Then if I change the direction of measuring device (the same measuring-spot) as the picture, I will got the measuring result variable, especially in L value - Delta L could vary -4, -2, -1, 0.5, etc, compared to the standard. I have tried another kind of matt-film lamination, adjusting the pressure of lamination machine. It still does not work.

So my question is: Do you know the caution of this phenomenon, what should I do for improvement?

I am very grateful for any idea and input from you!

Many thanks in advance.

Regards,

DeltaE

I am not sure this post suitable here or in color management area, please move it to correct area if needs!

I have to measure a color sample which is printed a spot color - standard L*a*b = (48.6, -0.50, -2.16) after matt-film lamination.

Measuring condition is D50/10 and M3 (with Polarized filter). My device is a eXact Standard with M3.

Then if I change the direction of measuring device (the same measuring-spot) as the picture, I will got the measuring result variable, especially in L value - Delta L could vary -4, -2, -1, 0.5, etc, compared to the standard. I have tried another kind of matt-film lamination, adjusting the pressure of lamination machine. It still does not work.

So my question is: Do you know the caution of this phenomenon, what should I do for improvement?

I am very grateful for any idea and input from you!

Many thanks in advance.

Regards,

DeltaE