gordo

Well-known member

I know this is "old school" however I would like to have the TVI data from a G7 certified (or ISO 12647 compliant) press sheet. Or you can give me the data file that I can extract the info from using ColorAnt.

I'm trying to make sense of the press gain curves from a G7 certified shop.

I can read a file with this header (and maybe others):

ORIGINATOR "i1Profiler - X-Rite, Inc."

INSTRUMENTATION "i1iO 2 ; Serial number 27248"

DESCRIPTOR "XTC_24_TestChart_Measurement_M1"

MEASUREMENT_SOURCE "MeasurementCondition=M1 Filter=D50"

ILLUMINATION_NAME "D50"

OBSERVER_ANGLE "2"

FILTER "D50"

WEIGHTING_FUNCTION "ILLUMINANT, D50"

WEIGHTING_FUNCTION "OBSERVER, 2 degree"

KEYWORD "DEVCALSTD"

DEVCALSTD "XRGA"

CREATED "2015-07-29T17:32:01"

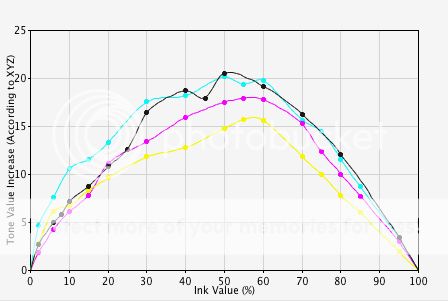

When I look at these press TVI curves:

or this:

...they look like a disaster. So I would like to see what other certified G7 press sheet curves look like to compare the difference.

Comments are also appreciated.

I'm trying to make sense of the press gain curves from a G7 certified shop.

I can read a file with this header (and maybe others):

ORIGINATOR "i1Profiler - X-Rite, Inc."

INSTRUMENTATION "i1iO 2 ; Serial number 27248"

DESCRIPTOR "XTC_24_TestChart_Measurement_M1"

MEASUREMENT_SOURCE "MeasurementCondition=M1 Filter=D50"

ILLUMINATION_NAME "D50"

OBSERVER_ANGLE "2"

FILTER "D50"

WEIGHTING_FUNCTION "ILLUMINANT, D50"

WEIGHTING_FUNCTION "OBSERVER, 2 degree"

KEYWORD "DEVCALSTD"

DEVCALSTD "XRGA"

CREATED "2015-07-29T17:32:01"

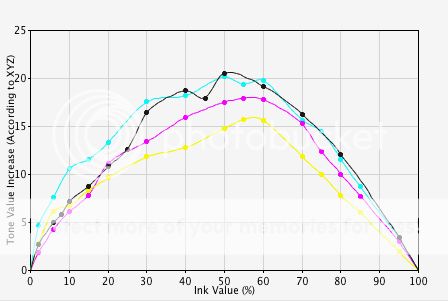

When I look at these press TVI curves:

or this:

...they look like a disaster. So I would like to see what other certified G7 press sheet curves look like to compare the difference.

Comments are also appreciated.

Last edited: