Kaoticor

Well-known member

Machine: Lithrone 28

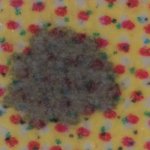

Problem Description: Getting what appears to be oil spots on the sheet.

Already did the usual thorough cleaning, checked the bearers for flinging oil, checked blanket wash cloths to make sure no rubbing. This is not a problem that is all the time and not always on the same job. It comes and goes and sometimes we won't notice it for quite a while then it will appear. Attached is a digital microscope picture. Any comments or thoughts as to what this might be?

After some investigating, you can definitely see these spots on the unit 1 impression cylinder, like it is being sprayed or flung. We brought it up to full speed then stopped, and the spots were visible on the sheets through unit 1. They seem to be visible on the unit 1 transfer cylinder as well. They are not visible on any others. Can't really seem to find the source. What is wierd though, is when the spots appear on the sheet, they will appear at the same spot for several revolutions. So it looks like a spraying, with the consistency of a print problem.

One other detail is after a morning startup, we didn't notice anything. About 2 hours in to the run, we had to shut down to make a small delivery adjustment. We were down 5 minutes, went right back up without changing anything else, and this problem was present immediately. Not sure if related but definitely seems a possibility.

Thanks in advance,

K

Problem Description: Getting what appears to be oil spots on the sheet.

Already did the usual thorough cleaning, checked the bearers for flinging oil, checked blanket wash cloths to make sure no rubbing. This is not a problem that is all the time and not always on the same job. It comes and goes and sometimes we won't notice it for quite a while then it will appear. Attached is a digital microscope picture. Any comments or thoughts as to what this might be?

After some investigating, you can definitely see these spots on the unit 1 impression cylinder, like it is being sprayed or flung. We brought it up to full speed then stopped, and the spots were visible on the sheets through unit 1. They seem to be visible on the unit 1 transfer cylinder as well. They are not visible on any others. Can't really seem to find the source. What is wierd though, is when the spots appear on the sheet, they will appear at the same spot for several revolutions. So it looks like a spraying, with the consistency of a print problem.

One other detail is after a morning startup, we didn't notice anything. About 2 hours in to the run, we had to shut down to make a small delivery adjustment. We were down 5 minutes, went right back up without changing anything else, and this problem was present immediately. Not sure if related but definitely seems a possibility.

Thanks in advance,

K

Attachments

Last edited: