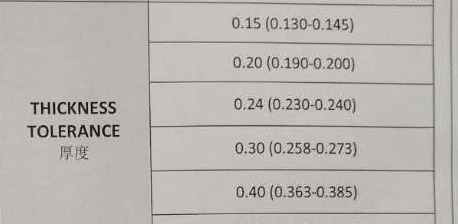

I had several thickness issues with a recent import from a Chinese supplier. Asked them about the problem and they sent a picture (attached below) and said it is "international standard". Is what they claim true or is it something fabricated to avoid responsibility?

Context: We purchased a large CTcP plate order last month which contained three different sizes in question: 560x670 (0.25mm & 0.30mm) and 600x730 (0.30mm). Their thickness before processing does not have any issues, however, 600x730 plates (0.30mm) after processing are only ~0.26mm (+-0.005mm), which supplier claimed to be ~0.265mm, while 560x670 (0.25mm) dropped to ~0.22mm.

We had a history of thickness issue with another supplier, and while this situation is not as severe as the previous, it is still damaging since our customers' machines cannot hold them in place (their machines are old and some cannot be adjusted). The bigger picture in this situation is that the plates is not usable after processing, while Huaguang plates received no complaints of thickness by anyone.

Context: We purchased a large CTcP plate order last month which contained three different sizes in question: 560x670 (0.25mm & 0.30mm) and 600x730 (0.30mm). Their thickness before processing does not have any issues, however, 600x730 plates (0.30mm) after processing are only ~0.26mm (+-0.005mm), which supplier claimed to be ~0.265mm, while 560x670 (0.25mm) dropped to ~0.22mm.

We had a history of thickness issue with another supplier, and while this situation is not as severe as the previous, it is still damaging since our customers' machines cannot hold them in place (their machines are old and some cannot be adjusted). The bigger picture in this situation is that the plates is not usable after processing, while Huaguang plates received no complaints of thickness by anyone.