We are running a Graphic Whizard PT 33LSC laminator with foil option. We are currently using Thermotype foils as are suggested by GW. Foiling on dense black toner with mixed results. Does anyone know of a different brand of foil that works on this machine? Max temp is 150 degrees top and bottom rollers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Toner reactive foils

- Thread starter Bobk

- Start date

brettbygrave

Member

I used sleeking from Smartech Business Solutions with good results once I found the right settings (different for each colour). Not sure where you are located but they appear to be worldwide.

Adhesion is hit or miss. If we are foiling multiples up on a sheet the foil drops off in random locationsWhat mixed results are you having?

criccidisk

Active member

We use Skandacor's line of sleeking foils on our Graphic Whizard with pretty solid results. Certain foils like silver are hit or miss, but I've gotten pretty good with darker or mid tone colors such as gold, red, and green that can hide blemishes a tiny bit better.

Graphic Whizard's advice about running the foil at the hottest possible temperature always seemed strange to me. When you put too much heat in the mix, the foil pretty much melts and shrinks on top of the toner without leaving a solid bond. Almost like shrinkwrap heating up. You'll end up with black toner around all of your edges.

My best results with the machine have been found with the following parameters (using KM toner):

* Using coated silk coverstock or coated silk label stock for one color work, or printing on top of their soft touch film for a foil overprint.

* Running the foil at a temperature of 113 - 118 Celsius, with no additional heat assistance from the bottom roller.

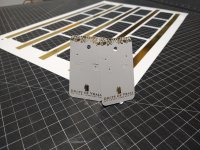

* Running black bars down the paper path of the press sheet to keep the foil evenly gripped to the sheet surface (see attached photo for an example press sheet in the background).

* There is a new board available for earlier PT 33 LSC units that adds a fifth speed setting that turbo-slows the machine to around 24 inches per minute. This super helps with foil adhesion, but really shows the weakness in how the unit regulates its roller temperatures. After 15 or so sheets, the rollers will start dramatically climbing in temperature since there's nowhere to dissipate its heat at such a slow speed. If I start to notice the foil curling around the target imprint and leaving black toner halos on the output, I open up the top cover of the machine to help get air inside the unit for cooling. I'll sometimes also raise or lower the roller pressure by one notch during this process. Too little heat, and you'll get speckles of toner in the body of the intended foil regions. Too much heat, and you'll get halos of black toner around the perimeter of your foil regions.

* The take up reel tension is also super important. I try to avoid having too much foil accumulate on the reel since it doesn't have enough torque to maintain the necessary tension long term. I'd encourage cleaning off your cardboard core on the take up reel after around 75 - 100 press sheets.

* The sounds of the machine are also super important; if you're hearing the foil crinkle prior to the take up reel, then one of the above notes/parameters is out of sorts and is causing the foil to prematurely pop off the press sheet before it's fully cooled down.

Happy foiling!

Graphic Whizard's advice about running the foil at the hottest possible temperature always seemed strange to me. When you put too much heat in the mix, the foil pretty much melts and shrinks on top of the toner without leaving a solid bond. Almost like shrinkwrap heating up. You'll end up with black toner around all of your edges.

My best results with the machine have been found with the following parameters (using KM toner):

* Using coated silk coverstock or coated silk label stock for one color work, or printing on top of their soft touch film for a foil overprint.

* Running the foil at a temperature of 113 - 118 Celsius, with no additional heat assistance from the bottom roller.

* Running black bars down the paper path of the press sheet to keep the foil evenly gripped to the sheet surface (see attached photo for an example press sheet in the background).

* There is a new board available for earlier PT 33 LSC units that adds a fifth speed setting that turbo-slows the machine to around 24 inches per minute. This super helps with foil adhesion, but really shows the weakness in how the unit regulates its roller temperatures. After 15 or so sheets, the rollers will start dramatically climbing in temperature since there's nowhere to dissipate its heat at such a slow speed. If I start to notice the foil curling around the target imprint and leaving black toner halos on the output, I open up the top cover of the machine to help get air inside the unit for cooling. I'll sometimes also raise or lower the roller pressure by one notch during this process. Too little heat, and you'll get speckles of toner in the body of the intended foil regions. Too much heat, and you'll get halos of black toner around the perimeter of your foil regions.

* The take up reel tension is also super important. I try to avoid having too much foil accumulate on the reel since it doesn't have enough torque to maintain the necessary tension long term. I'd encourage cleaning off your cardboard core on the take up reel after around 75 - 100 press sheets.

* The sounds of the machine are also super important; if you're hearing the foil crinkle prior to the take up reel, then one of the above notes/parameters is out of sorts and is causing the foil to prematurely pop off the press sheet before it's fully cooled down.

Happy foiling!

Attachments

Thank you!We use Skandacor's line of sleeking foils on our Graphic Whizard with pretty solid results. Certain foils like silver are hit or miss, but I've gotten pretty good with darker or mid tone colors such as gold, red, and green that can hide blemishes a tiny bit better.

Graphic Whizard's advice about running the foil at the hottest possible temperature always seemed strange to me. When you put too much heat in the mix, the foil pretty much melts and shrinks on top of the toner without leaving a solid bond. Almost like shrinkwrap heating up. You'll end up with black toner around all of your edges.

My best results with the machine have been found with the following parameters (using KM toner):

* Using coated silk coverstock or coated silk label stock for one color work, or printing on top of their soft touch film for a foil overprint.

* Running the foil at a temperature of 113 - 118 Celsius, with no additional heat assistance from the bottom roller.

* Running black bars down the paper path of the press sheet to keep the foil evenly gripped to the sheet surface (see attached photo for an example press sheet in the background).

* There is a new board available for earlier PT 33 LSC units that adds a fifth speed setting that turbo-slows the machine to around 24 inches per minute. This super helps with foil adhesion, but really shows the weakness in how the unit regulates its roller temperatures. After 15 or so sheets, the rollers will start dramatically climbing in temperature since there's nowhere to dissipate its heat at such a slow speed. If I start to notice the foil curling around the target imprint and leaving black toner halos on the output, I open up the top cover of the machine to help get air inside the unit for cooling. I'll sometimes also raise or lower the roller pressure by one notch during this process. Too little heat, and you'll get speckles of toner in the body of the intended foil regions. Too much heat, and you'll get halos of black toner around the perimeter of your foil regions.

* The take up reel tension is also super important. I try to avoid having too much foil accumulate on the reel since it doesn't have enough torque to maintain the necessary tension long term. I'd encourage cleaning off your cardboard core on the take up reel after around 75 - 100 press sheets.

* The sounds of the machine are also super important; if you're hearing the foil crinkle prior to the take up reel, then one of the above notes/parameters is out of sorts and is causing the foil to prematurely pop off the press sheet before it's fully cooled down.

Happy foiling!

Similar threads

- Replies

- 0

- Views

- 3523

- Replies

- 0

- Views

- 2492

PressWise

|

A 30-day Fix for Managed Chaos

As any print professional knows, printing can be managed chaos. Software that solves multiple problems and provides measurable and monetizable value has a direct impact on the bottom-line. “We reduced order entry costs by about 40%.” Significant savings in a shop that turns about 500 jobs a month. Learn how……. |