pacificiam

Well-known member

Hi...

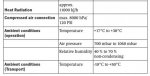

We are purchasing new CTP. Hence we required to set up new CTP room for it.

Kindly guide me to setup this room and what required to make it ideal room.

Please do the needful

We are purchasing new CTP. Hence we required to set up new CTP room for it.

Kindly guide me to setup this room and what required to make it ideal room.

Please do the needful