Excellent stuff above, and totally accurate, but WAY beyond the scope of what's called for here.

Do a "LOAD-ENTER" with all the covers open. Watch the film and the 2 moveable arms.

What you will probably see is the supply side (left) arm start to go down, then pop back up.

The system is losing tension on the supply side of the film. Likely causes include the supply cassette, or the supply drive motor. If the film is not properly on the cassette, or the ends are not latched tight, if it is possible to spin the film roll on the shaft, the machine won't work. Open the cassette, and make sure the film is centered, and both sides are latched tight. a common error is to have one side in the 14" position, the other in the 12" position, and 13.3" film. You can't latch both ends, and the film will spin.

The other common problem is the supply motor. It is mounted on a spring loaded hinged flap. The spring gets loose, or the hinge breaks. The hinge breaks so often that made a new one, available (from me) as a mod kit. Wiggle the motor around, if it flops all over the hinge is broken.

The pictures show the mod kit, and the lit installed in a machine. If yours looks different, you don't have it.

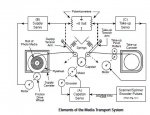

A good test of the media drive system is to do a motor cleaning (options - enter, select to motor cleaning, enter) The system will spin the supply and takeup motors (not the capstain, see diagram above) If you move the tensioner rollers down, you can change the speed on the motors. If you can speed up and slow down both motors, the media feed system is working properly.