Hi folks,

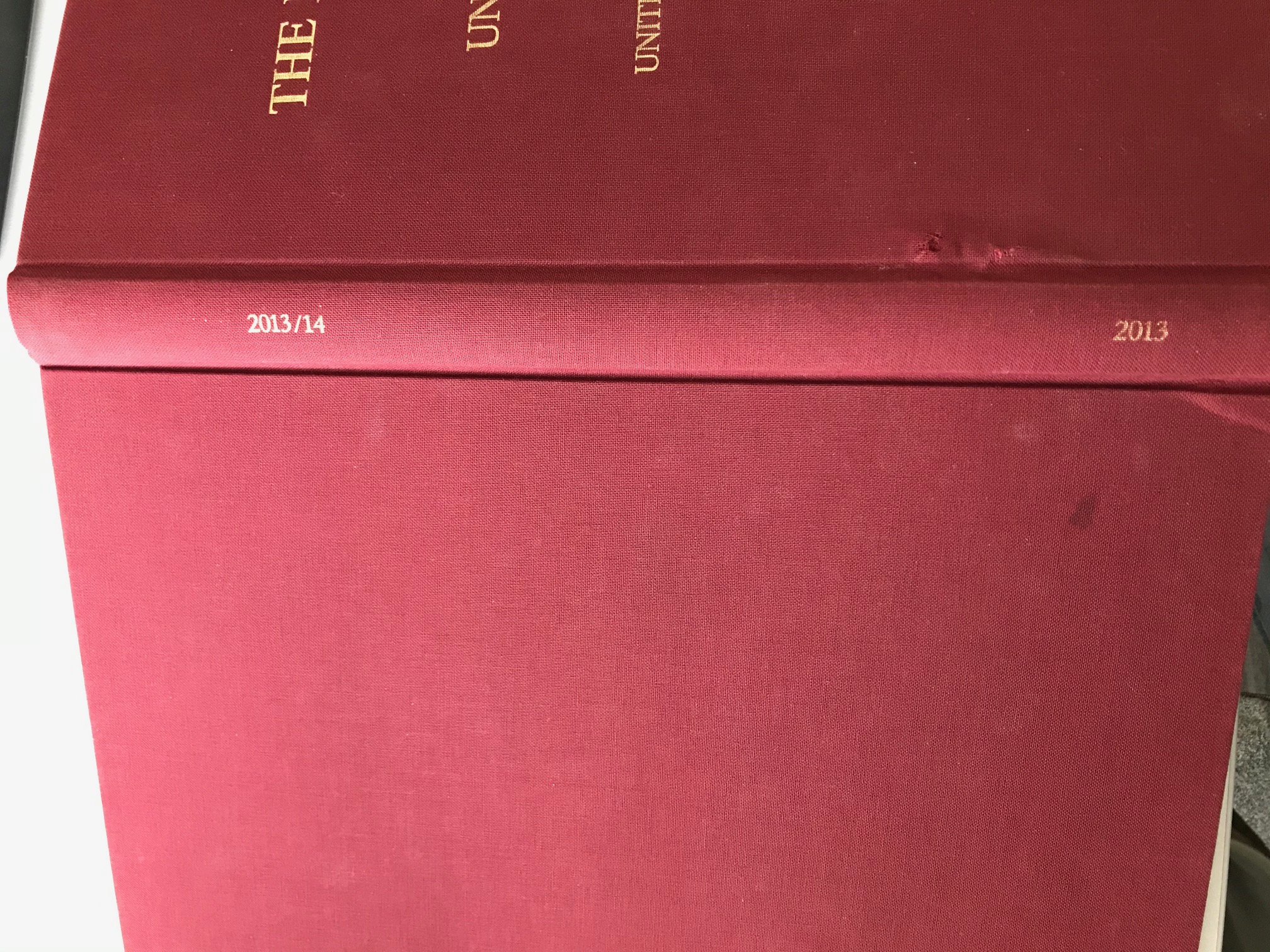

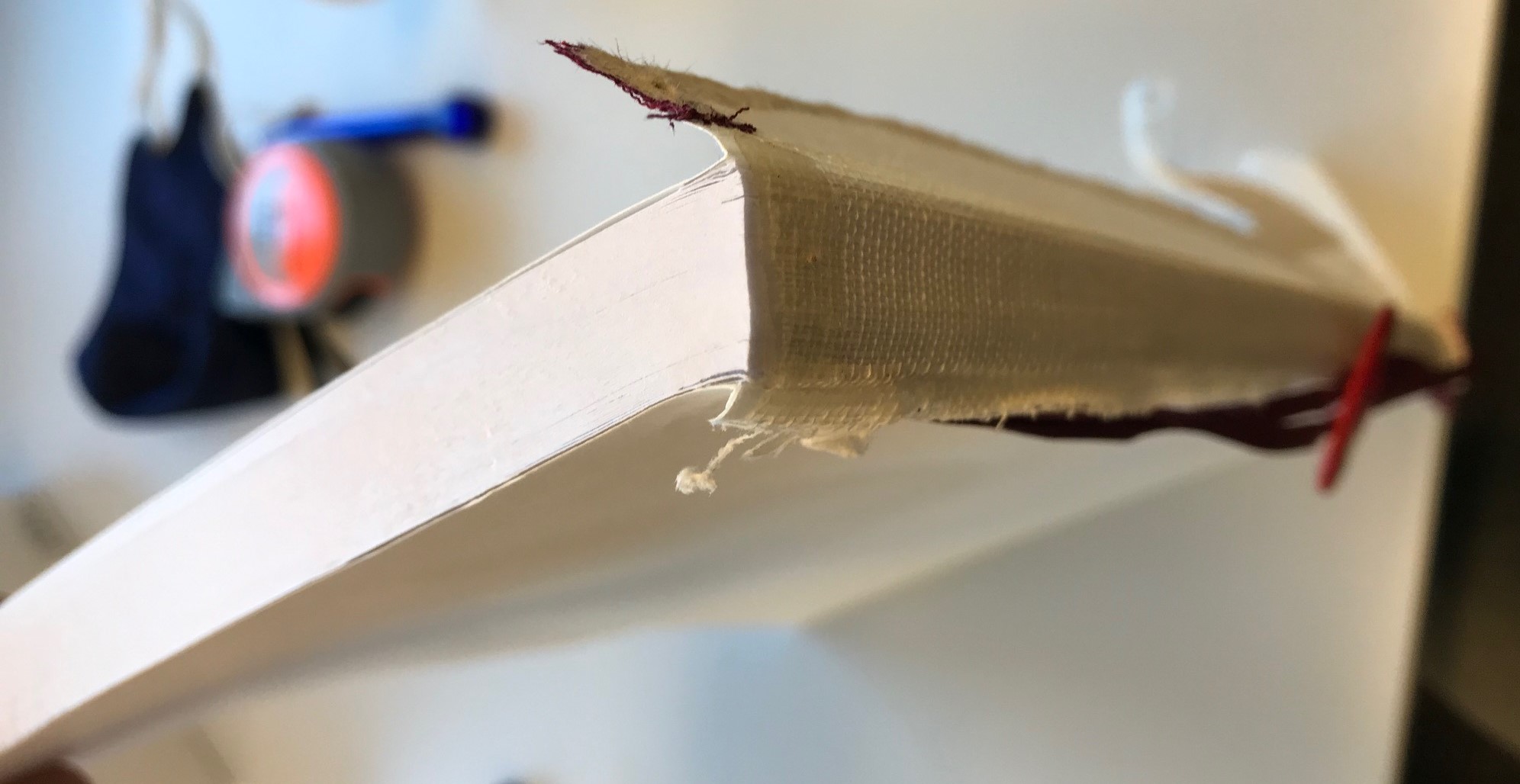

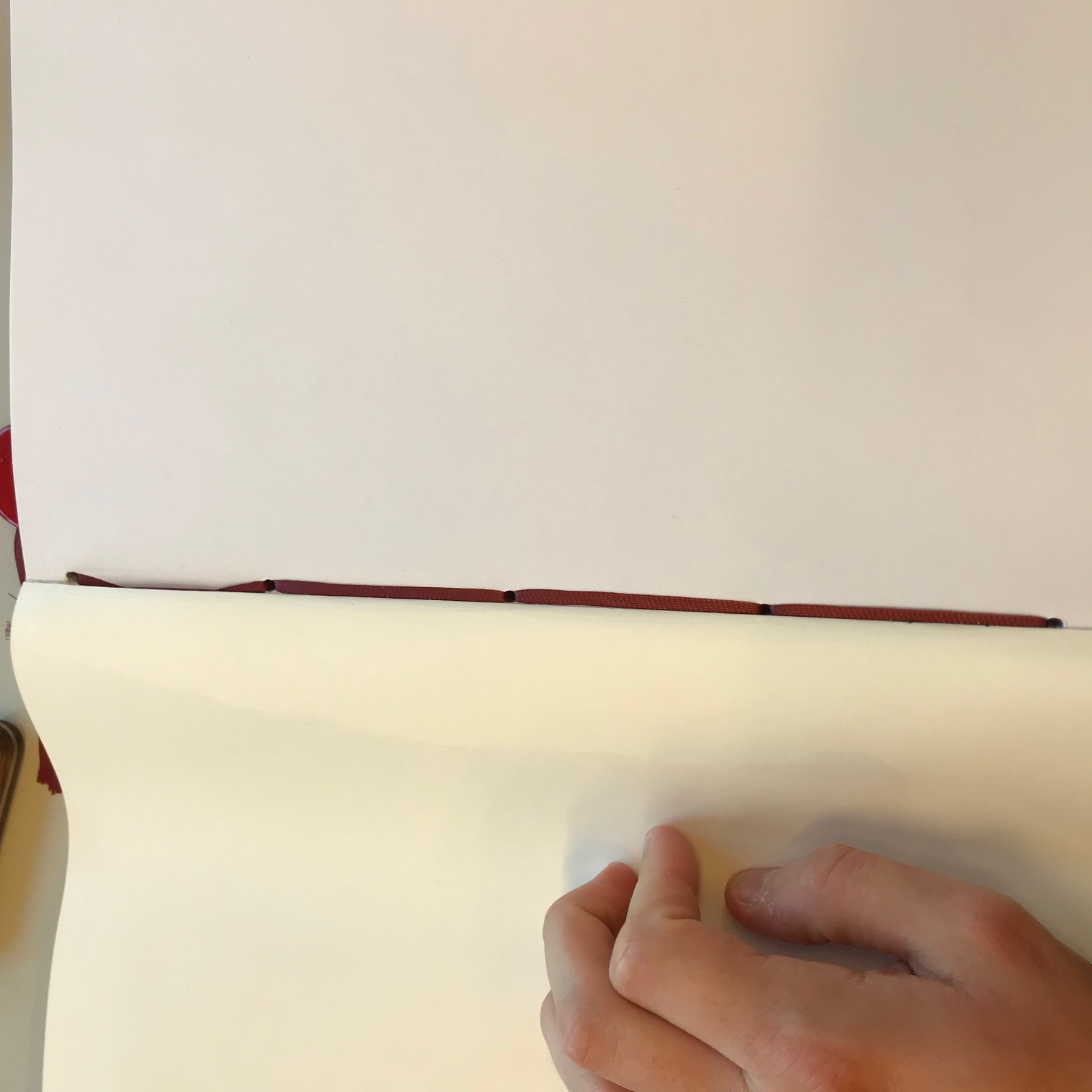

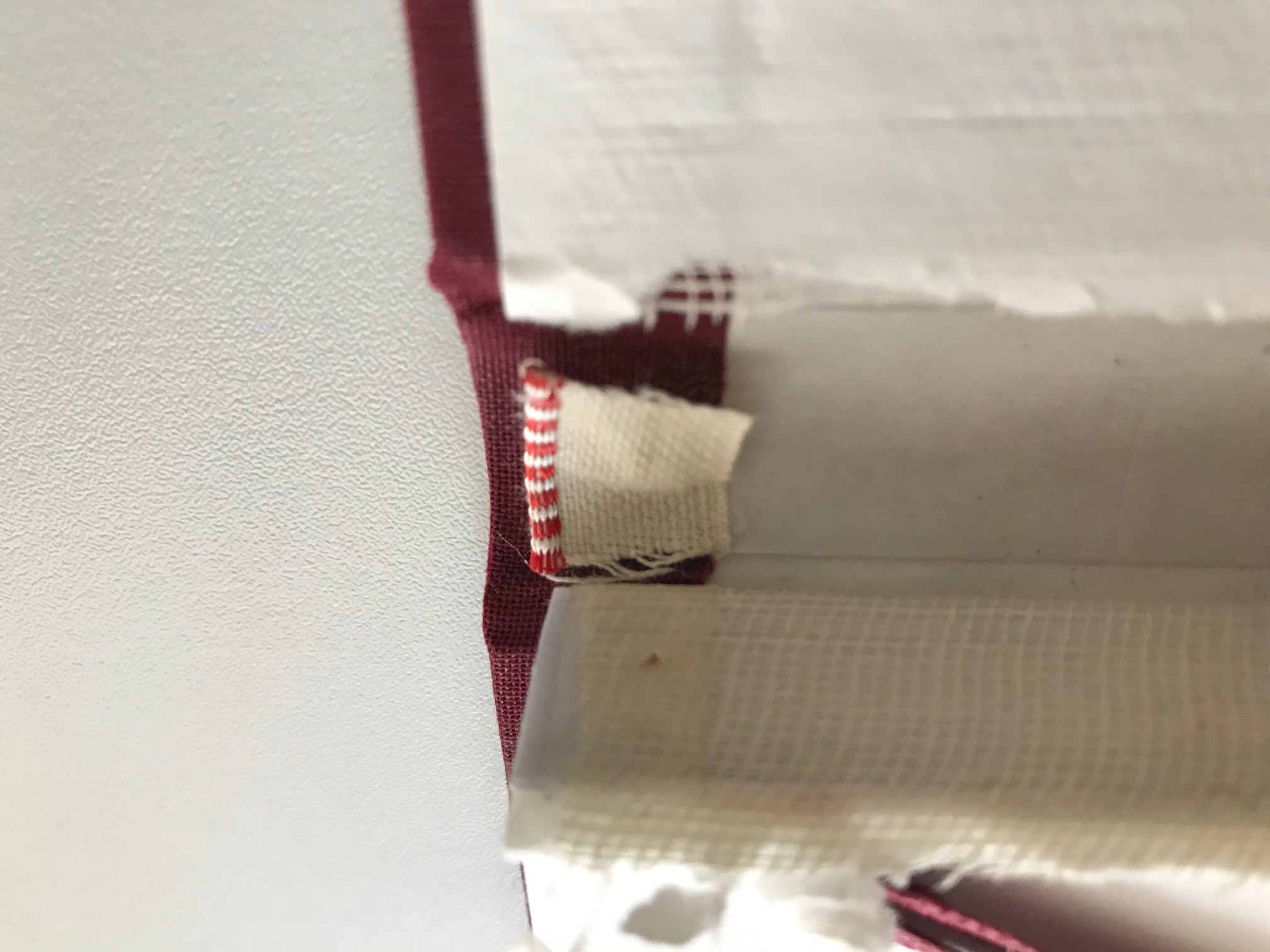

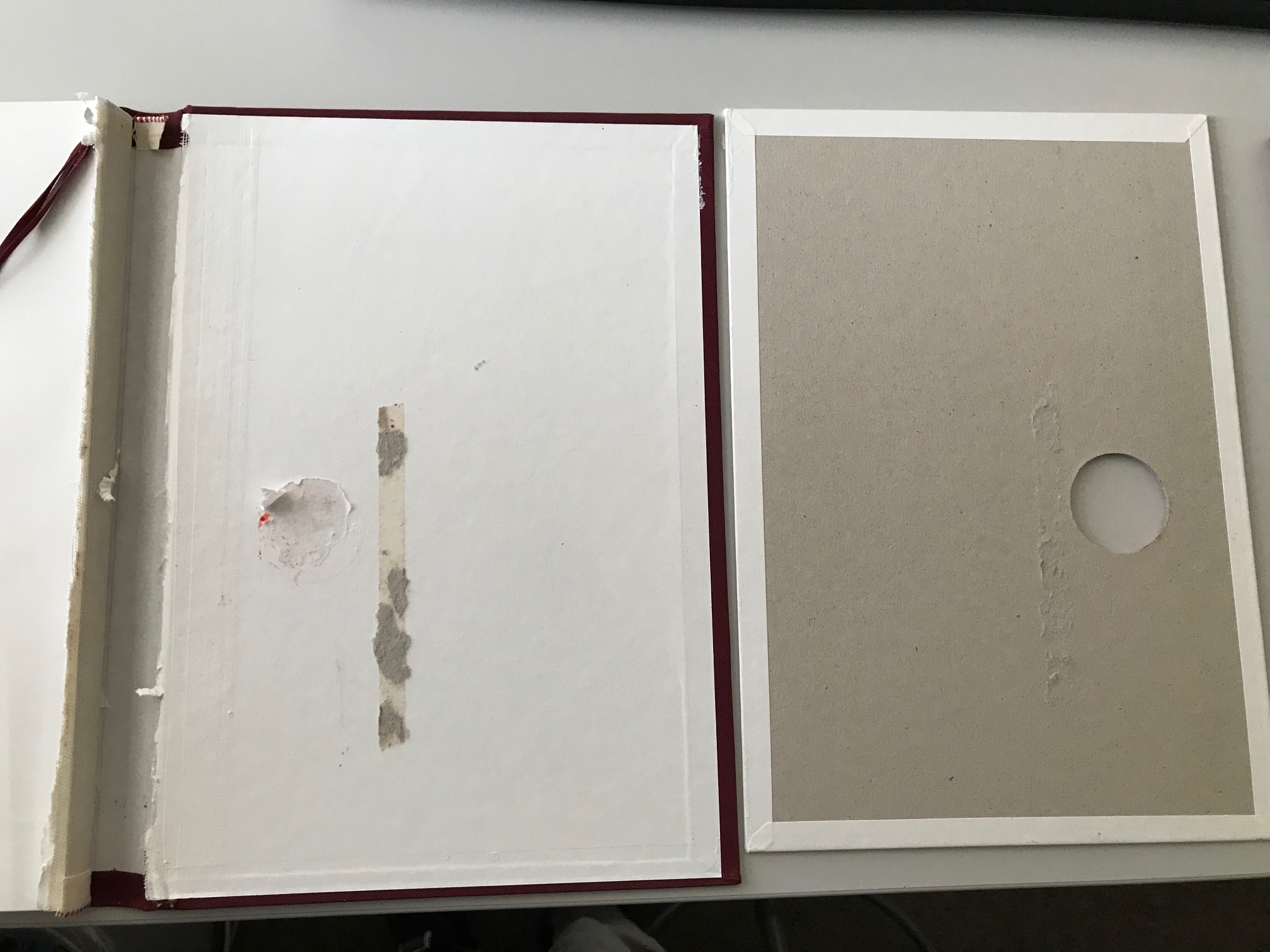

Please see below snaps of a book we had bound by a now defunct bindery. I took it apart to try and figure out how it was done, and how we can replicate it.

I thought they had done it all completely by hand, but looking closer I wonder whether a system like the Powis Fastback with their hard covers and headbands may have been used. The glue strips and little stick on headbands make me suspicious.

We're getting a fastback binder anyway for simple tape binds by non-technical staff, and I want to see if we can replicate the below type of bind using their hard covers. I don't expect the same standard of finish, 75% of the quality would do it. I'll get a foil stamping machine for the cover text, and a custom wax stamp with our logo on it to seal the ribbon. I suppose I would need a small diamater drill to drill the holes into the pages to feed the coloured ribbon through.

Thoughts and advice gladly appreciated!

Powis hard covers -

Please see below snaps of a book we had bound by a now defunct bindery. I took it apart to try and figure out how it was done, and how we can replicate it.

I thought they had done it all completely by hand, but looking closer I wonder whether a system like the Powis Fastback with their hard covers and headbands may have been used. The glue strips and little stick on headbands make me suspicious.

We're getting a fastback binder anyway for simple tape binds by non-technical staff, and I want to see if we can replicate the below type of bind using their hard covers. I don't expect the same standard of finish, 75% of the quality would do it. I'll get a foil stamping machine for the cover text, and a custom wax stamp with our logo on it to seal the ribbon. I suppose I would need a small diamater drill to drill the holes into the pages to feed the coloured ribbon through.

Thoughts and advice gladly appreciated!

Powis hard covers -