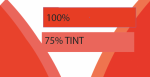

We have a customer supplied file that has a Spot Color named "Special Orange" that was created with a 4-color process mix of cyan-0 / magenta-85 / yellow-100 / black-0. We needed to convert the Spot to Process to multiply into a grayscale photo under it, maintaining the exact color. When we convert to process, the mix stays the same, but the on-screen preview changes a lot.

Weirdly they have one spot fill (multiply/transparency 75%) over another spot file (multiple/transparency 75) over the grayscale. That shouldn't be an issue.

But why would a spot color created with a process mix change visually when converted to process?

TIA

Linda

Weirdly they have one spot fill (multiply/transparency 75%) over another spot file (multiple/transparency 75) over the grayscale. That shouldn't be an issue.

But why would a spot color created with a process mix change visually when converted to process?

TIA

Linda