You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HOW TO LINEARIZE A CTP KODAK TRENDSETTER

- Thread starter CHAVEZ

- Start date

gordo

Well-known member

There is no need to do that.Dear colleagues, could you help me how to linearize a CTP Kodak Trendsetter ?? It is running with Prinergy Kodak Workflow.

I appreciate your help.

Thank you

CHAVEZ

Well-known member

Gordo, Thank you for your help, that means that is not necessary do any calibration to get the right percent of dots ?? If I send 25% of screen I will get this 25% automatically ??There is no need to do that.

Again thank you..

gordo

Well-known member

Gordo, Thank you for your help, that means that is not necessary do any calibration to get the right percent of dots ?? If I send 25% of screen I will get this 25% automatically ??

Again thank you..

Calibration was done when your ctp was set up. It was done to create robust dots and a clean background on the plate.

When you request a 25% dot you may or may not get a 25% dot on the plate. That does not matter. You are not selling plates to your print buyers - you are selling presswork.

What matters is what tone value at that 25% request that you get on the press sheet.

You create a dot gain/tone reproduction compensation curve based on:

1 - the specified tone value in the original file

2 - the measured tone value on the press sheet at that requested tone value

3 - the target tone value on the press sheet for that tone value

For example:

1 - you have a 50% tone value specified in my original file

2 - that 50% request results in a 60% tone value on the press sheet

3 - your target for a 50% tone in the file is 65%

So you create a dot gain/tone reproduction compensation curve to map the 50% tone in the file so that you get the target 65% on the press sheet.

The tool to do this is Harmony software (I don't know if Kodak still uses it though)

As far as the plate is concerned - it's job is to be consistent when imaged.

More info here:

The principle of dot gain compensation plate curves

In a film workflow the industry standard was to create film output that was linear. This meant that a 25% tone request in the original Posts...

CHAVEZ

Well-known member

Dear Gordo, I appreciate your help, I am going to analyze this information and I will let you know the advance or status about this CTP. Great day for you.. Thank youCalibration was done when your ctp was set up. It was done to create robust dots and a clean background on the plate.

When you request a 25% dot you may or may not get a 25% dot on the plate. That does not matter. You are not selling plates to your print buyers - you are selling presswork.

What matters is what tone value at that 25% request that you get on the press sheet.

You create a dot gain/tone reproduction compensation curve based on:

1 - the specified tone value in the original file

2 - the measured tone value on the press sheet at that requested tone value

3 - the target tone value on the press sheet for that tone value

For example:

1 - you have a 50% tone value specified in my original file

2 - that 50% request results in a 60% tone value on the press sheet

3 - your target for a 50% tone in the file is 65%

So you create a dot gain/tone reproduction compensation curve to map the 50% tone in the file so that you get the target 65% on the press sheet.

The tool to do this is Harmony software (I don't know if Kodak still uses it though)

As far as the plate is concerned - it's job is to be consistent when imaged.

More info here:

The principle of dot gain compensation plate curves

In a film workflow the industry standard was to create film output that was linear. This meant that a 25% tone request in the original Posts...the-print-guide.blogspot.com

Harmony still exists, and I still use it, but Kodak are trying to move users to Colorflow.Calibration was done when your ctp was set up. It was done to create robust dots and a clean background on the plate.

When you request a 25% dot you may or may not get a 25% dot on the plate. That does not matter. You are not selling plates to your print buyers - you are selling presswork.

What matters is what tone value at that 25% request that you get on the press sheet.

You create a dot gain/tone reproduction compensation curve based on:

1 - the specified tone value in the original file

2 - the measured tone value on the press sheet at that requested tone value

3 - the target tone value on the press sheet for that tone value

For example:

1 - you have a 50% tone value specified in my original file

2 - that 50% request results in a 60% tone value on the press sheet

3 - your target for a 50% tone in the file is 65%

So you create a dot gain/tone reproduction compensation curve to map the 50% tone in the file so that you get the target 65% on the press sheet.

The tool to do this is Harmony software (I don't know if Kodak still uses it though)

As far as the plate is concerned - it's job is to be consistent when imaged.

More info here:

The principle of dot gain compensation plate curves

In a film workflow the industry standard was to create film output that was linear. This meant that a 25% tone request in the original Posts...the-print-guide.blogspot.com

CHAVEZ

Well-known member

Dear Magnus59, I appreciate your information, I will work with my customer and I hope do the right job. Good day, take care.Harmony still exists, and I still use it, but Kodak are trying to move users to Colorflow.

CHAVEZ

Well-known member

Dear Magnus59, I forgot do you know where May I learn more about Harmony ? Thank you…Harmony still exists, and I still use it, but Kodak are trying to move users to Colorflow.

Creating curves in Harmony - Prinergy System Administration Guides 8.1 - Kodak Workflow DocumentationDear Magnus59, I forgot do you know where May I learn more about Harmony ? Thank you…

gordo

Well-known member

I think that link is for flexo. Here's for offset: ColorFlow User Guide - ColorFlow 7.5 - Kodak Workflow Documentation

Last edited:

SZmetana

Member

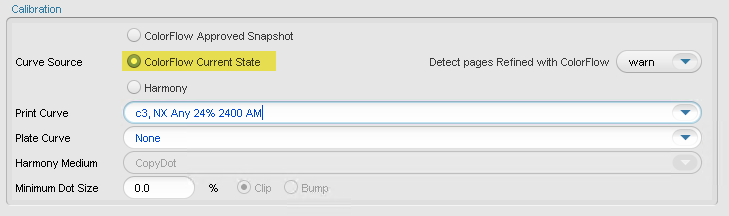

You can continue to use the Harmony to do tonal calibration for Kodak Prinergy, but Kodak recommends you make the switch to ColorFlow. Harmony just does single-channel adjustment of values, it doesn't know anything about the "color" of your presswork. ColorFlow Workflow Edition is included with every Prinergy system and allows you to create gray-balance curves or align to G7 or any of the latest print specifications such as GRACoL and FOGRA. Even if you're not measuring print results and just creating transfer curves (ie. entering a bunch of numbers the platemaking department gave you), ColorFlow has a very simple UI and allows you to copy and paste from a spreadsheet or text file right into ColorFlow. Once in Prinergy, just select ColorFlow as your curve source and select curves as you normally would.

Similar threads

- Replies

- 6

- Views

- 589

InSoft Automation

|

InSoft Automation Unveils Imp Version 14

Revolutionizing Layout Planning and Automation InSoft Automation announces the launch of Imp Version 14, the latest iteration of its industry-leading cost-based layout planning software. Packed with cutting-edge features, this release redefines efficiency, automation, and workflow optimization for printing and finishing processes. Learn more……. |