Albert Noel

Well-known member

ive been having some issues lately with movement during the course of a run on my roland 300.

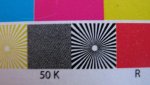

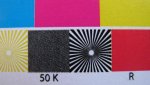

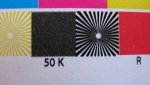

it seems that the higher the press speed, the more movement i get. problem is, it's only in one unit. (the unit we use for black) at speeds up to and including 10,000 sph, things print normally. i get good crisp dots in the 50% and no slur/doubling. though, as i increase speed, say 1000 sph at a time, it gets progressively worse to the point that by the time i get to 14-15k sph my register marks clearly show the black plate being out of register. not able to produce quality sheets at these speeds anymore and thus taking alot longer on some runs than normal. this happens on all stock weights and sizes.

i originally though it was the infeed head stops but they are fine/zero/calibrated and then focused on the transfer grippers leading from the infeed back to the the third unit and all seem to be in spec using a feeler guage. the only thing i can think of now is that there is either plate movement or the grippers still arent right on the impression cylinder for that unit.

the blanket is properly torqued, packed correctly and the plates a punched properly and as far as i can tell the plate clamp on the press is set correctly.

does it sound more like a gripper issue or a plate issue?

it seems that the higher the press speed, the more movement i get. problem is, it's only in one unit. (the unit we use for black) at speeds up to and including 10,000 sph, things print normally. i get good crisp dots in the 50% and no slur/doubling. though, as i increase speed, say 1000 sph at a time, it gets progressively worse to the point that by the time i get to 14-15k sph my register marks clearly show the black plate being out of register. not able to produce quality sheets at these speeds anymore and thus taking alot longer on some runs than normal. this happens on all stock weights and sizes.

i originally though it was the infeed head stops but they are fine/zero/calibrated and then focused on the transfer grippers leading from the infeed back to the the third unit and all seem to be in spec using a feeler guage. the only thing i can think of now is that there is either plate movement or the grippers still arent right on the impression cylinder for that unit.

the blanket is properly torqued, packed correctly and the plates a punched properly and as far as i can tell the plate clamp on the press is set correctly.

does it sound more like a gripper issue or a plate issue?

Last edited: