Hello,

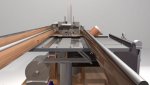

I am trying to build a perfect binder for a non-profit org that is on a tight budget.

I was wondering if anyone could provide me with the following details:

1) How high should the nipper be? (I am thinking 1/8 inch)

2) How much pressure should the nipper exert on the book? Is there a minimum/maximum? (I am guessing at least 50 lbs. and maybe no more than 200 lbs.)

3) With how much pressure should the cover be pressed against the book block prior to the nipper closing? (I am working with PUR.)

4) How thick should the PUR film be? (I am thinking .25mm)

Please let me know if I need to provide more details. I will welcome any kind of feedback!

Thank you.

I am trying to build a perfect binder for a non-profit org that is on a tight budget.

I was wondering if anyone could provide me with the following details:

1) How high should the nipper be? (I am thinking 1/8 inch)

2) How much pressure should the nipper exert on the book? Is there a minimum/maximum? (I am guessing at least 50 lbs. and maybe no more than 200 lbs.)

3) With how much pressure should the cover be pressed against the book block prior to the nipper closing? (I am working with PUR.)

4) How thick should the PUR film be? (I am thinking .25mm)

Please let me know if I need to provide more details. I will welcome any kind of feedback!

Thank you.