dean112263

Member

We are a folding carton plant and run all Heidelberg XL-145's. Have been running Fuji plates for past 4 years (LH-PJ). Had to switch to LH-PJ2 plates (mfg. in Japan) a few months ago.

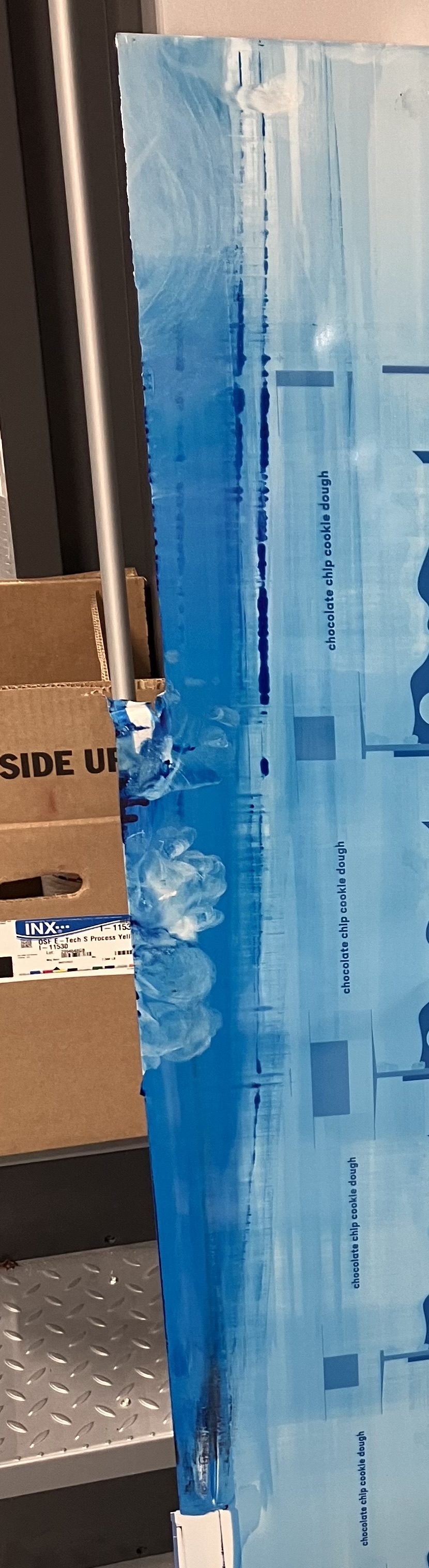

Encountering something re: the tail edge of the plates (2 images attached)

The first image was from one of our older XL-145s. This damage occurred 8/26. The second one was one of several units from a brand new XL-145 that was just installed about 3 months ago.

We already had the newer press' tail clamps checked by Heidelberg service techs (and they were adjusted). Even since the adjustment we had the shredded tail of occur only on runs over 50,000 (usually occurring between 50-70m sheets). We've had it happen on SBS and CCNB stock.

We've used the same print blankets for all of our presses (hybrid type of blanket since we print conv., some UV/Hybrid and a small amt of pure UV.

We did not encounter this problem with the LH-PJ's (manufactured in Greenwood, SC). We used the LH-PJ's for approx. 3 years prior to switch to LH-PJ2's

Haven't been able to pinpoint root cause yet.

Since it was only happening on our new press, we were thinking it's purely a mechanical / clamp issue.

But with this happening on another press also only on a >50,000 sheet run I feel it may be more of raw materials / plate issue.

Have our Fuji tech rep coming in to examine.

Has anyone else encountered this issue with LH-PJ2 plates?

Any insight anyone can provide is appreciated.

Encountering something re: the tail edge of the plates (2 images attached)

The first image was from one of our older XL-145s. This damage occurred 8/26. The second one was one of several units from a brand new XL-145 that was just installed about 3 months ago.

We already had the newer press' tail clamps checked by Heidelberg service techs (and they were adjusted). Even since the adjustment we had the shredded tail of occur only on runs over 50,000 (usually occurring between 50-70m sheets). We've had it happen on SBS and CCNB stock.

We've used the same print blankets for all of our presses (hybrid type of blanket since we print conv., some UV/Hybrid and a small amt of pure UV.

We did not encounter this problem with the LH-PJ's (manufactured in Greenwood, SC). We used the LH-PJ's for approx. 3 years prior to switch to LH-PJ2's

Haven't been able to pinpoint root cause yet.

Since it was only happening on our new press, we were thinking it's purely a mechanical / clamp issue.

But with this happening on another press also only on a >50,000 sheet run I feel it may be more of raw materials / plate issue.

Have our Fuji tech rep coming in to examine.

Has anyone else encountered this issue with LH-PJ2 plates?

Any insight anyone can provide is appreciated.