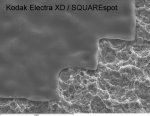

Well I did not think it would come to this but it seems that the string wants to go quite deep into the anatomy of a plate’s grain structure, which is fine by me. I love to share this type of information. Gordo shows a great picture of the grained structure though I have attached a couple more images below which show the EC grain structure much closer as well as the anodic layer (Anodizing) that Alois refers to. Along with this I have outlined the 6 processes that a plate goes through in the creation of an EC grained substrate, for those who care to venture further.

The process of preparing an aluminum web for coating entails six different stages, including Metal Prep, Electro-chemical Graining, Etch, Desmut, Anodizing and Post Treatment.

Metal Prep – This process is intended to remove all dirt, oils and grime that might interfere with the graining process.

Electrochemical Graining - As mentioned in my earlier post, the formation of an EC Grain structure is created by the combination of sulfuric acid and electricity working in concert with the conductive properties of the aluminum to produce a surface that is pitted with random cells which vary in diameter, depth, and frequency due to the non-uniform nature of the alloys composition. This structure can be controlled though the dwell time in the acid, temperature, acid concentration, and/or the amount of electrical current applied. By altering these variables, a manufacturer will create differing grain structures which will create the needed characteristics for press latitude, water carrying uniformity, and adhesion.

Etch – The Etch process, which is an alkaline bath, is utilized to neutralize the graining acid while removing embedded abrasive particles of aluminum and smoothing any sharp peaks that were created during the graining process. One negative that comes from this process however is the creation of a black smut which is caused by the reaction of the etch chemical with the non-aluminum metals, such as copper, that are found in litho grade aluminum alloys.

Desmut – This process is just as the name denotes, the removal of the black smut that is formed during etching. This step will have no affect on the actual grain structure, though is crucial for surface preparation prior to anodizing.

Anodizing – The anodizing process is one of the most crucial stages in the creation of a litho plate as it provides the plate with many of its characteristics for run length, scratch resistance, and chemical resistance. Due to the fact that aluminum is a very soft and malleable metal, if we were to send the plate to press the pressures and abrasive nature of lithographic printing would destroy the grain almost instantly. The process of Anodizing creates a hard layer of aluminum oxide (second hardest substance known to man next to a diamond) on top of the grain structure which retains the previously created structure. This newly formed anodic layer will tend to vary in thickness based on plate type, the desired characteristics, and manufacture and can be a crucial characteristic in choosing the right plate for a given application. Although this layer is extremely hard it does not mean that it will not break down, in fact many plates that fail for run length are due to the wearing of the anodic layer and not the emulsion. Many long run plates purposely carry a thicker anodic layer (high oxide) to ensure that the non image area will not break down causing late run tinting, toning and picture framing as well as unpredictable changes to ink/water balance through the run. If any of you have ever taken a plate off the press and it is nice and shiny then you have depleted the anodic layer.

Post Treat - The last stage of the substrate preparation is the Post Treatment of the grained surface. Now, not all manufactures will do this process, but what it is intended to do is to promote better adhesion of the plate emulsion while also pre-treating the surface to improve water loving (hydrophilic) characteristics during the initial press start. This treatment will help a pressman achieve a faster make ready and color establishment as the ink and water balance is achieved much quicker. This layer will actually be abraded away very quickly (first few thousand impressions) when it is then replaced by the wetting agents found in the fountain solution. If you have ever seen a plate run great for the first few thousand impressions and then begin to catch up, this is a clear sign that the fountain solution is not providing ample non image area protection and it should be remixed or replaced.

We are now ready to apply a coating.

This concludes anatomy of a grain structure 101. Quiz on Friday.