ssutton503

Active member

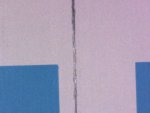

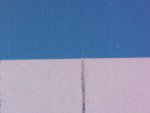

We are a commercial print shop running Goss Community presses. In the last 3 months we have been experiencing what I will call "scratches" that print on the finished product. On a newspaper page, the scratches run top to bottom and are hairline thickness. I have attached 4 photos we took with a magnifying camera. Sometimes it looks like an actual scratch from top to bottom and other times it looks like the plate was beat with a piece of chain. We have only seen these scratches on cyan and magenta units but they have appeared on multiple towers. I have now seen scratches on plates from 2 different manufacturers (our regular plate is processed and the new plate was "No-Process"). The scratch will not be on the plate at the beginning of a run but develops as the run goes along. It might show as early as 1000 impressions or it might take longer.

Anybody seen anything like this? Any guesses as to the cause?

Anybody seen anything like this? Any guesses as to the cause?