Elton McAleer

Member

Hi all.

I am setting up ISO 12647-2 plate curves for paper type 1&2 on a komori Lithotrone 28. Whilst I am aware that komoris are said to print a 'sharp' dot, I am getting some very strange results when running linear plates to calculate the mechanical gain and then compensate to the desired TVI.

I have set up lots of presses over the last few months, and 'typically' the linear gain before compensation is in the region of 19 -25% at 50 (eg a 50%tint prints at 69-75). This is fine, and is easily corrected with a plate compensation curve to bring the TVI in line with the standard (In this case, 14.3% CMY and 16%K at 50%).

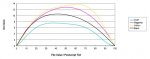

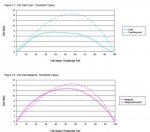

On the komori in question, I am seeing a strange linear result on Cyan in particular, (graphs attached) although all four colours are gaining less than i would usually expect to see.

NOTE: these curves are before any plate/press compensation is applied.

The Cyan is only gaining by a max of approx 8% and seems to be 'flat' from quarter tones to shadows - rather than the usual smooth, 'high' linear result.

I have checked blankets (packing and torque) roller settings and shore, fountain solution, alcohol, plate calibration, etc etc, but am still getting a 'poor transfer' of the dot. I suspect there may be a mechanical problem on the cyan unit but am not a press engineer so I don't really know where to suggest the customer starts.

Paper is 115gsm matte coated, ink conforms to ISO and is not thinned, pressroom and press temperatures are all within spec.

Has anyone seen this kind of 'flat curve' before? Care to suggest what might be causing it?

I use Kodak Tonal Curve Toolkit and GMG Print Control to establish my figures.

Curves are generated from 400 sheet (after make ready) run to wet densities to give dry LABs that meet PaperType 1, 5 sets of 10 sheets, 50 measurements averaged by TCT to smooth data over run and across sheet.

Thanks guys,

Elton

(Fogra PSO implementation partner)

I am setting up ISO 12647-2 plate curves for paper type 1&2 on a komori Lithotrone 28. Whilst I am aware that komoris are said to print a 'sharp' dot, I am getting some very strange results when running linear plates to calculate the mechanical gain and then compensate to the desired TVI.

I have set up lots of presses over the last few months, and 'typically' the linear gain before compensation is in the region of 19 -25% at 50 (eg a 50%tint prints at 69-75). This is fine, and is easily corrected with a plate compensation curve to bring the TVI in line with the standard (In this case, 14.3% CMY and 16%K at 50%).

On the komori in question, I am seeing a strange linear result on Cyan in particular, (graphs attached) although all four colours are gaining less than i would usually expect to see.

NOTE: these curves are before any plate/press compensation is applied.

The Cyan is only gaining by a max of approx 8% and seems to be 'flat' from quarter tones to shadows - rather than the usual smooth, 'high' linear result.

I have checked blankets (packing and torque) roller settings and shore, fountain solution, alcohol, plate calibration, etc etc, but am still getting a 'poor transfer' of the dot. I suspect there may be a mechanical problem on the cyan unit but am not a press engineer so I don't really know where to suggest the customer starts.

Paper is 115gsm matte coated, ink conforms to ISO and is not thinned, pressroom and press temperatures are all within spec.

Has anyone seen this kind of 'flat curve' before? Care to suggest what might be causing it?

I use Kodak Tonal Curve Toolkit and GMG Print Control to establish my figures.

Curves are generated from 400 sheet (after make ready) run to wet densities to give dry LABs that meet PaperType 1, 5 sets of 10 sheets, 50 measurements averaged by TCT to smooth data over run and across sheet.

Thanks guys,

Elton

(Fogra PSO implementation partner)