zamir

Member

Dear friends,

We, at Printiv Press, Israel, are using The Indigo 7200 digital narrow press,

to print short-run books.

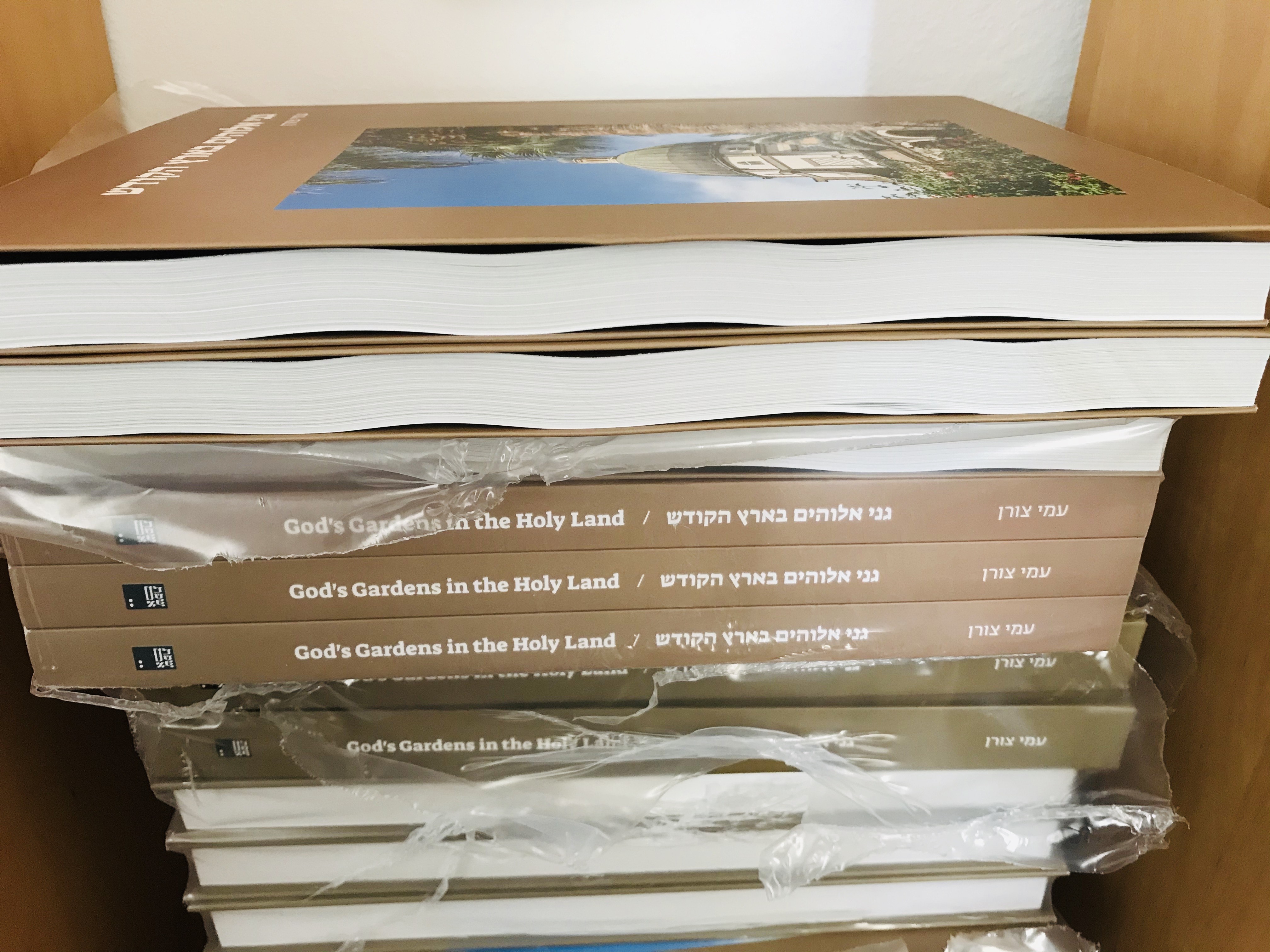

As the paper is fed from rolls, the A4 books are printed against

the paper grain directions, so from time to time, we are facing this problem

of "Waves'' on the inside pages. See the image below.

The customer refuses to receive these books (4000$ order!).

Has anybody an idea how to straighten the pages?

Some say, leave it alone for a few weeks at the open air and they

will get straight back and others say put them under pressure for a while.

Any help will be appreciated.

Zamir Bar-Lev

Printiv Press

Jerusalem, ISRAEL

[email protected]

www.printiv.co.il

We, at Printiv Press, Israel, are using The Indigo 7200 digital narrow press,

to print short-run books.

As the paper is fed from rolls, the A4 books are printed against

the paper grain directions, so from time to time, we are facing this problem

of "Waves'' on the inside pages. See the image below.

The customer refuses to receive these books (4000$ order!).

Has anybody an idea how to straighten the pages?

Some say, leave it alone for a few weeks at the open air and they

will get straight back and others say put them under pressure for a while.

Any help will be appreciated.

Zamir Bar-Lev

Printiv Press

Jerusalem, ISRAEL

[email protected]

www.printiv.co.il

Last edited: