A Chipless Solution for Mimaki Printers?

By LFP Repair Services

In today’s digital world, we are accustomed to instant and convenient solutions that save us time and money. We use email instead of traditional mail and send electronic copies of documents to avoid the cost and hassle of printing and shipping. So, why not apply these principles to the ink loading systems of printers?

Traditionally, printers require physical ink chips to function properly. These chips act as a medium for digital information. They are necessary for the printer to recognize the type of ink, color of ink, and ink level in a printer. But, with recent developments in ink chip technology, a new solution has emerged—introducing the Ink Chip Emulator—also known as the chipless solution.

An Ink Chip Emulator allows printers to function without the need for physical ink chips. Instead, they utilize electronic files to send ink information to the printer.

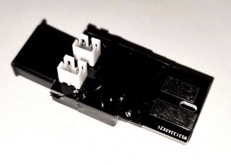

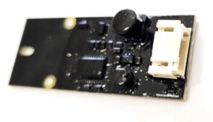

The Ink Chip Emulator uses a USB data cable on one side, which can be loaded with any ink data file, and an ink chip on the other, which can be inserted into the printer.

Once loaded with the ink file through USB, the Ink Chip Emulator gets recognized by the printer and the printer accepts all necessary parameters such as the ink type, color (CMYK, W, Cl, etc.) & ink level (initially set at 100%).

With an Ink Chip Emulator, users no longer need physical ink chips for printing. They can load any ink data into the Emulator over and over again with a click of a mouse. Using an Ink Chip Emulator in printers can offer several benefits, including:

Ink Chip Emulators come with step-by-step instructions and online support to help users with the initial setup. In general, setting up an Ink Chip Emulator involves downloading the necessary software, plugging the USB stick into a computer, and loading the ink data file onto the Emulator. Once loaded with the ink data file, it can be inserted into the printer's ink slot like a physical ink chip.

While setting up an Ink Chip Emulator may require a bit of initial effort, the long-term benefits of cost savings, convenience, and sustainability make it well worth it. And with the availability of support resources and compatibility checks, users can rest assured that they can easily integrate this technology into their printing operation.

By LFP Repair Services

In today’s digital world, we are accustomed to instant and convenient solutions that save us time and money. We use email instead of traditional mail and send electronic copies of documents to avoid the cost and hassle of printing and shipping. So, why not apply these principles to the ink loading systems of printers?

Traditionally, printers require physical ink chips to function properly. These chips act as a medium for digital information. They are necessary for the printer to recognize the type of ink, color of ink, and ink level in a printer. But, with recent developments in ink chip technology, a new solution has emerged—introducing the Ink Chip Emulator—also known as the chipless solution.

An Ink Chip Emulator allows printers to function without the need for physical ink chips. Instead, they utilize electronic files to send ink information to the printer.

The Ink Chip Emulator uses a USB data cable on one side, which can be loaded with any ink data file, and an ink chip on the other, which can be inserted into the printer.

Once loaded with the ink file through USB, the Ink Chip Emulator gets recognized by the printer and the printer accepts all necessary parameters such as the ink type, color (CMYK, W, Cl, etc.) & ink level (initially set at 100%).

With an Ink Chip Emulator, users no longer need physical ink chips for printing. They can load any ink data into the Emulator over and over again with a click of a mouse. Using an Ink Chip Emulator in printers can offer several benefits, including:

- Chip cost savings: Ink data files are significantly cheaper than physical ink chips. This significantly reduces the overall cost of printing. Ink Chip Emulators also completely avoid shipping costs.

- Convenience: Data files for an Ink Chip Emulator deliver instantly. You only need to load ink files to the Ink Chip Emulator whereas with physical chips, you need to order them and then wait for shipping. This saves you time and hassle.

- Printing cost savings: Updating ink chip data allows you to continue using the ink cartridge even when the printer indicates the cartridge is empty, which can help to reduce the cost of printing.

- Usually ink data files can be used on multiple printers to dramatically reduce cost of production.

- Environmentally friendly: Reusing ink cartridges by updating Ink Chip Emulators can help to reduce waste and promote sustainability. This entirely avoids the environmental cost of producing and shipping physical ink chips.

- Customization: The Emulator can be loaded with different files as many times as needed. Ink Chip Emulators can even work for multiple printers through the emulator’s customization options.

- Variety of choices: Physical ink chips lock you into a specific ink manufacturer. Using an emulator opens up your printer to other ink manufacturers.

Ink Chip Emulators come with step-by-step instructions and online support to help users with the initial setup. In general, setting up an Ink Chip Emulator involves downloading the necessary software, plugging the USB stick into a computer, and loading the ink data file onto the Emulator. Once loaded with the ink data file, it can be inserted into the printer's ink slot like a physical ink chip.

While setting up an Ink Chip Emulator may require a bit of initial effort, the long-term benefits of cost savings, convenience, and sustainability make it well worth it. And with the availability of support resources and compatibility checks, users can rest assured that they can easily integrate this technology into their printing operation.