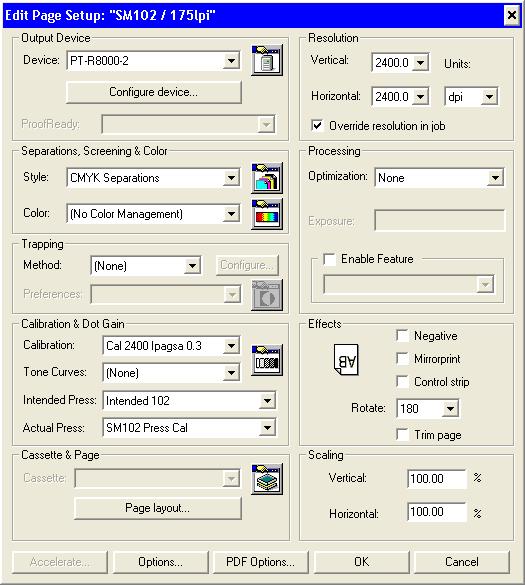

Gordo, does that mean we do not have to adjust dot gain for plate and press? In my rip, harelquin, there are fields to input the intended and outputed results so that the rip compensates. Currently i have values added to linearize plates just in case i want to use a different plate, and so that i can control quality every day by exposing a plate and doing some fine tuning IF necessary. I also have added the intended dot gain for my presses and then entered the gains after printing and measuring DRY paper. So the gain for each press was added. What's confusing is that according to latest standards TVI, tone value increase is used instead of dot gain, and I am not sure if my INTENDED numbers need to go in a tone curve instead. I've been using xrite spectroeye to read dotgain off paper. How do you read TVI, do you have to read lab values then convert to profile cmyk?

Dot gain and TVI are the same thing and they are measured the same way. TVI is just a more accurate way of describing what's going on.

I don't know what your harlequin is doing with the data that you enter - I suspect it may be creating some kind of dot gain curve. I don't know.

Maybe look at the issue from another angle.

Say I tell you that I want you to print at the ISO specification - i.e. your target is 15% dot gain/TVI. (i.e. at 50% you get 15% dot gain).

Now, what if you're printing with 20 micron FM. With a linear plate you'll get perhaps 30% gain. There is no way for you to get 15% dot gain/TVI. If you apply a curve to the plate, you will still not get 15% dot gain/TVI.

However, if instead I told you that the target was a 65% tone on press where a 50% tone was requested, then there is no problem. You create a curve for the plate that maps a 50% request to whatever tone on plate creates a 65% tone on press.

If you first linearize your plates with a curve then you will be using 2 curves (one to linearize and the other to change the tonal response on press). Using two curves on top of one another adds complexity (and potential for error) for no benefit. Perhaps you could be even be using a plate curve but need to hit a new standard. At that point you could conceivably be using 3 curves - one to linearize, one on top of that to achieve your current standard and another one on top of those to hit the new standard. This is likely why GRACoL suggested that you don't bother. It's natural to think you should, after all in the film days that was standard practice since linear film was the defacto file interchange format. But with CtP it is not needed.

If you apply a curve to the plate that makes the plate linear, and that allows you to hit the target tones (not dot gain/TVI) on press then your linearizing curve is effectively a dot gain/TVI compensation curve.

If that is the set up that works and you now what to change parameters, e.g. different substrates, different SIDs, different press, different plate type, you would run an uncalibrated (likely non-linear) plate and check its tonal response compared with your standard. You would then create a single tone curve to bring your uncalibrated plate press response in line with your existing calibrated press response.

If, out of the box, your plate imaging is not consistent, i.e. 50% is sometimes 47% and sometimes 55% you won't have a stable enough system on which to build any curves - including linearization curves. Unless you are wanting to create linearization curves for every plate or batch of plates or state of the chemistry.

You are certainly correct in measuring dry paper/ink. Typically the press operator does not measure dot gain/TVI - just SIDs (that's another thread though) since he has basically no controls for dot gain/TVI on the press. However, if at the press dot gain/TVI is for some reason measured (perhaps in a closed loop press control system) and the measurements are of wet densities (i.e. no coatings) then you need to adjust targets based on the effect of dryback.

best, gordon p