Polyprintgirl

Active member

Hi, wondering if anyone has any ideas how to prevent highlight dot "dropoff". We are running 1.5 mil polyethylene with .067" photopolymer plates w/.020" backing tape, with 120L screens.

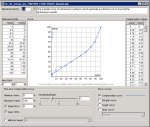

One jpg shows the dropoff on the printed poly, the other file shows the dgc applied to the job. We'd bumped the highlights initially because they had been dropping out on press, but now we're wondering if we need to run a separate dgc for gradations.

Thanks in advance for any comments.

One jpg shows the dropoff on the printed poly, the other file shows the dgc applied to the job. We'd bumped the highlights initially because they had been dropping out on press, but now we're wondering if we need to run a separate dgc for gradations.

Thanks in advance for any comments.