Dear friends,

I am medium level printer from South India. I have recently installed

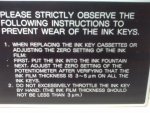

Mitsubishi-1F-5 colour machine . This machine i bought from Canada. It is good machine and the year is 1999. About 67 miill impresions. There is small problem in Ink key settings.

if we set the inks for example at 15 scale fro Key no 1 to Key no 21 . but in printing the

the colour are not even. I even changed the Ink key motors, but issue is still there. Any Service engineers pl advice .

thanks

Ganesh

I am medium level printer from South India. I have recently installed

Mitsubishi-1F-5 colour machine . This machine i bought from Canada. It is good machine and the year is 1999. About 67 miill impresions. There is small problem in Ink key settings.

if we set the inks for example at 15 scale fro Key no 1 to Key no 21 . but in printing the

the colour are not even. I even changed the Ink key motors, but issue is still there. Any Service engineers pl advice .

thanks

Ganesh