indy jones

Well-known member

What is the process for calibrating for Orange and Green on offset press? We have Curves 3 to calibrate. We have our press calibrate to Gracol 2006 and XCMYK. Any good pdf for quidance?

We are new to this Hexachrome setup. Orange and Green because we have an Epson 9000 with Orange and Green ink setup. We are hoping to calibrate the press and create an icc profile to see if we can match our press. I am open for what Orange and Green ink to use. Screening Conventional and FM.

You need to make sure that the inks used for the O and G are designed to run as "process" colors (i.e. be screened and wet trapped). This is a major point of failure in EG printing and can be exacerbated with FM screening. The below are some examples - your results may appear different. The key is that the integrity of the ink lay down should be similar to your process ink lay down (assuming the your process printing is as it should be).

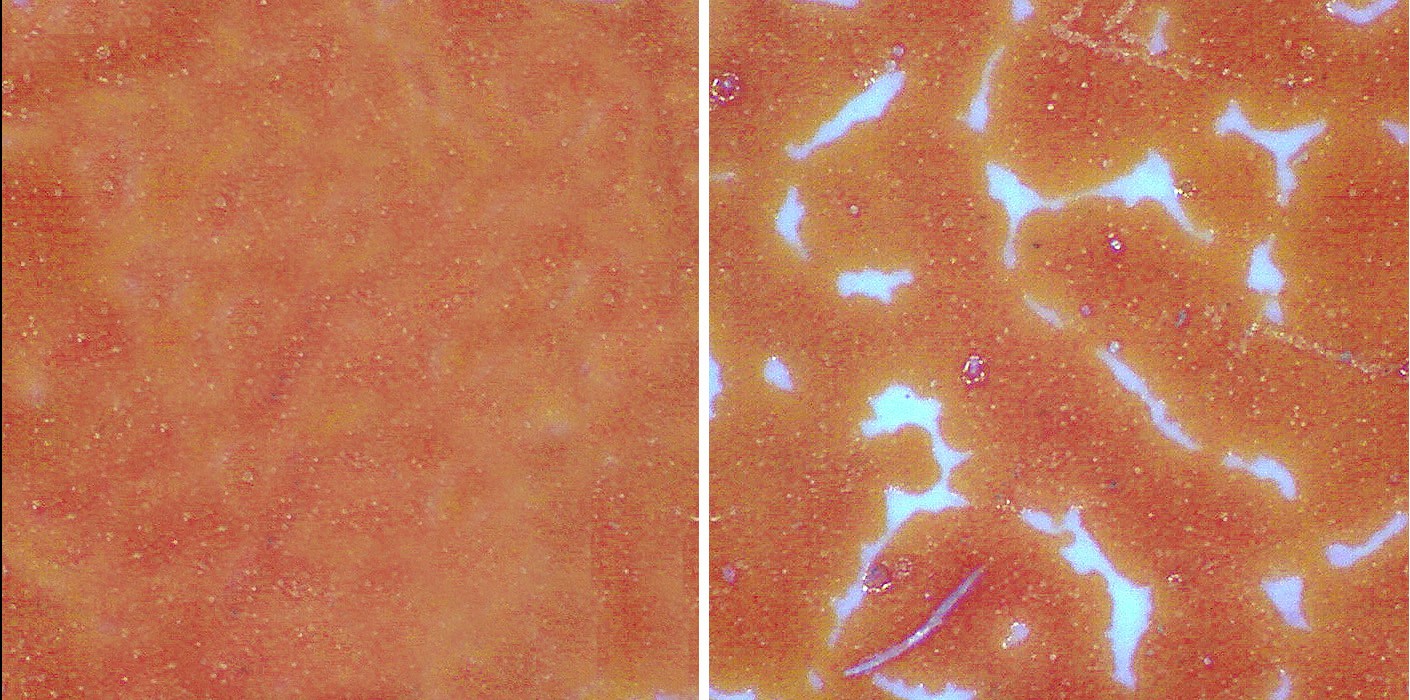

On the left is a solid O ink formulated correctly and on the right a solid O ink incorrectly formulated:

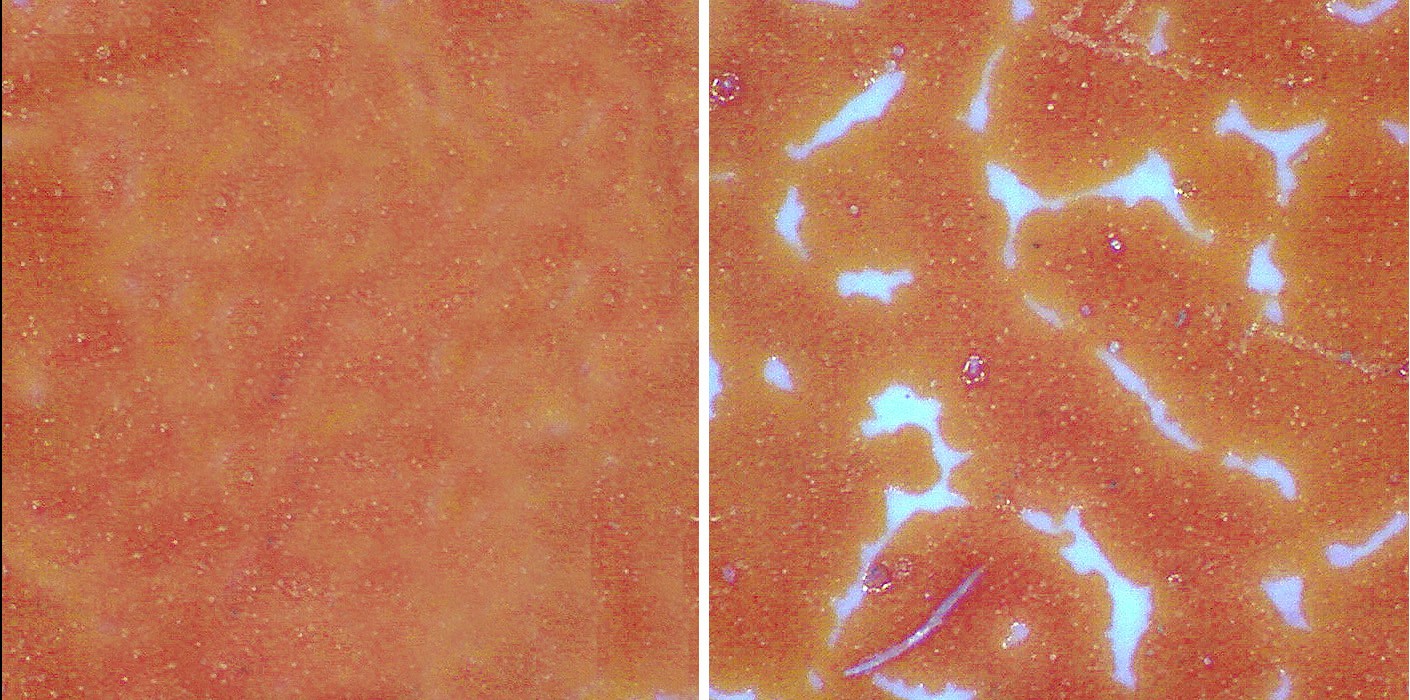

A screened area of the O ink incorrectly formulated:

There are several methods that printers use to build a dot gain curve for extended process colors:

1) Use the Black curve

2) Use the curve of the closest process ink hue (in your case the Cyan curve)

3 Build a curve the conventional way (target curve plus press response = compensation curve)

A fairly common ink hue for O is PMS 151 and PMS 7481 for green.

You should also confirm how your RIP assigns screen angles. With AM screening some RIPs simply assign the Black angle to any channels more than 4, others cycle through the KCMY angles over again. With FM you should see if there are screen patterns specific for channels beyond CMYK or how it handles those extra channels.

Does it make since to get ink hue from our Epson 9000 which has orange and green ink and match for our press orange and green?

|

A 30-day Fix for Managed Chaos

As any print professional knows, printing can be managed chaos. Software that solves multiple problems and provides measurable and monetizable value has a direct impact on the bottom-line. “We reduced order entry costs by about 40%.” Significant savings in a shop that turns about 500 jobs a month. Learn how……. |