BeauchampT

Well-known member

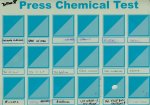

My plant is looking into some new plates. In some discussions with our supplier he suggested that we do a fresh chemical audit and do some "drop tests" on our plates (drop some chemical on an unimaged plate and see the result on the emulsion to check if any of our chemicals are uncompatible with the plate).

He recommended a basic image that would be helpful (kind of a visual measurement strip). Anyone have a suggestion in this regard??

He recommended a basic image that would be helpful (kind of a visual measurement strip). Anyone have a suggestion in this regard??