Howdy,

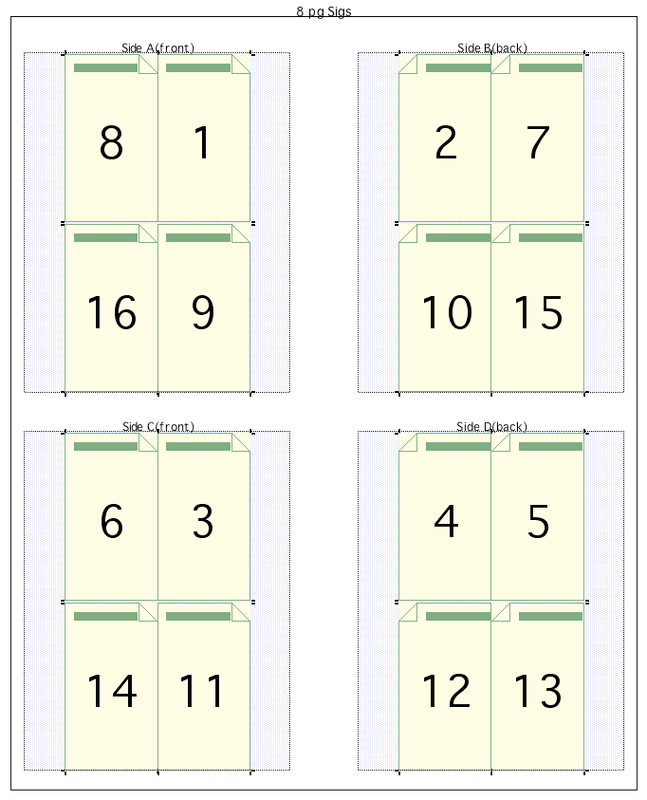

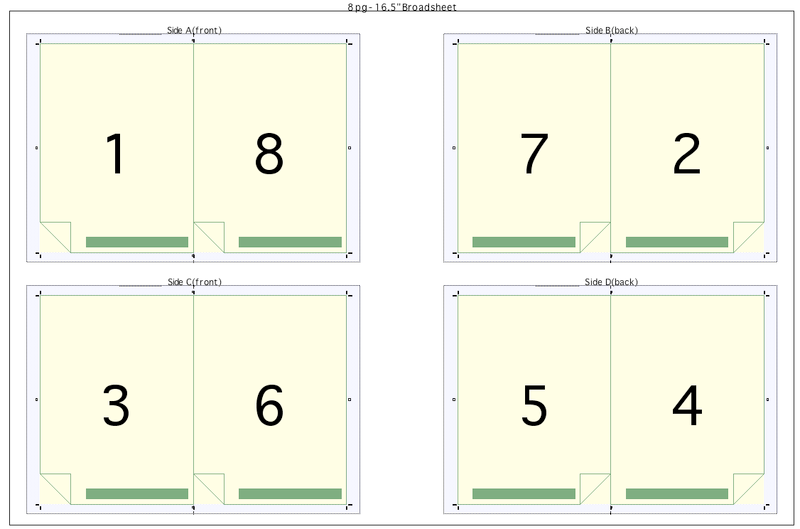

Is there a process, or formula, or seat-of-the-pants way to number a web press Preps layout? For example, I need a 96pg book layout, 8 pg per side, 2 sides per web, 2 webs per 32 pg sig, three 32pg sigs for the whole job.

I tried to renumber an old 80pg layout, but it didn't look right and, well, I got scared. Any thoughts would be appreciated.

Thanks, y'all, Rick

Is there a process, or formula, or seat-of-the-pants way to number a web press Preps layout? For example, I need a 96pg book layout, 8 pg per side, 2 sides per web, 2 webs per 32 pg sig, three 32pg sigs for the whole job.

I tried to renumber an old 80pg layout, but it didn't look right and, well, I got scared. Any thoughts would be appreciated.

Thanks, y'all, Rick