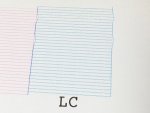

I have been getting horizontal banding in my cyan when printing. First I thought it was due to a clogged inkjet, but after cleaning and testing I see that the light cyan has an alignment issue. Every jet is clean, but the edges of the light cyan test strip show that there is a wiggle on each side. I have done a number of alignment cycles, but that did not change it at all. When printing a file that has any solid blues, I get banding from this defect. Is this fixable? Does anyone have any suggestions?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Print head alignment and banding of light Cyan on P9000

- Thread starter colourz

- Start date

Igor Kovalchuk

Member

I think problem with print head but this very badly situation. But before you need testing with another ink you can take new cartridge preferably this year and clean ink system after fill new ink if problem solve you lucky man if not afraid need clean print head but this need time and special equipment. Additional question how many years this printer work with this print head?

I would guess that the print head was damaged - the nozzles have been deflected by some type of crash - paper gap too tight, a tear in the paper, etc. The Epson 1 time repair program - for 1395.00 in the US - will cover a print head replacement (and you should push for a new capping station (normal maintenance) as well).

The printer is less than 1.5 years old with just average usage. I have own an Epson 9600, 9800, 9880, 9890 and now a P9000 and this is the first time I have ever seen this issue or had to replace a print head. I have way more clogged jets with the newer models than I ever had with the early models.I think problem with print head but this very badly situation. But before you need testing with another ink you can take new cartridge preferably this year and clean ink system after fill new ink if problem solve you lucky man if not afraid need clean print head but this need time and special equipment. Additional question how many years this printer work with this print head?

I am in Canada, and there does not look like a similar program. There is a good service company in Vancouver, but that is a ferry ride away in a Covid-19 world. To add insult to injury, my other Epson 9890 is also have clogged head issues (stubborn clog in the LK channel). Talked to Epson yesterday, they didn't ever try to trouble shoot, they have never seen anything like this.I would guess that the print head was damaged - the nozzles have been deflected by some type of crash - paper gap too tight, a tear in the paper, etc. The Epson 1 time repair program - for 1395.00 in the US - will cover a print head replacement (and you should push for a new capping station (normal maintenance) as well).

schenkadere

Well-known member

I have to agree with you. I have 3 P9000's and an SC-T5270...they all clog like mad. I think they're designed that way to waste ink with forced cleanings, in turn, forcing the consumer to purchase more ink.The printer is less than 1.5 years old with just average usage. I have own an Epson 9600, 9800, 9880, 9890 and now a P9000 and this is the first time I have ever seen this issue or had to replace a print head. I have way more clogged jets with the newer models than I ever had with the early models.

Epson's phone support is pitiful. I have figured out every issue on my own way before they had "solutions" that didn't work anyway.

Igor Kovalchuk

Member

Dear Colourz you must determine you want make service for your printer by himself or not if yes you will have to provide service and this will be not easily some time. If you don’t want recovery by himself better wait when service company start work.

Because you problem can't be solved by magically (like press one button and all Work!!) this not your situation.

Your problem will keep three general ways:

1. Ink;

2. Clean unit in printer (parking station);

3. Print head (worst option).

Thereby you must step-by-step check and exclude possible options.

Start from newest Ink because if problem will be in not with Ink you can use then in future and you not will lose money. If this not ink I explain you how check parking station but this will be next step.

About newest Epson printers they don’t have more problem than oldest model the this is next oldest print head have nozzle size average 4pl newest print head have 1.5pl this provide more quality but maintenance need more responsible and VERY IMPORTANT environmental conditions (temperature, humidity and CLEAN ) if you don’t want make more maintenance and provide good environmental conditions just no buy Epson printers or buy old model from Ebay.

PS: your printer don’t have any problem with electronic and firmware therefore don’t touch them. Otherwise you can make worse.

Because you problem can't be solved by magically (like press one button and all Work!!) this not your situation.

Your problem will keep three general ways:

1. Ink;

2. Clean unit in printer (parking station);

3. Print head (worst option).

Thereby you must step-by-step check and exclude possible options.

Start from newest Ink because if problem will be in not with Ink you can use then in future and you not will lose money. If this not ink I explain you how check parking station but this will be next step.

About newest Epson printers they don’t have more problem than oldest model the this is next oldest print head have nozzle size average 4pl newest print head have 1.5pl this provide more quality but maintenance need more responsible and VERY IMPORTANT environmental conditions (temperature, humidity and CLEAN ) if you don’t want make more maintenance and provide good environmental conditions just no buy Epson printers or buy old model from Ebay.

PS: your printer don’t have any problem with electronic and firmware therefore don’t touch them. Otherwise you can make worse.

Horace Ezasse

Member

We have two P9000s - two years old. Both are absolutely worthless. We had to roll out the old P9880s and put them back online. The P9000s developed either a deflected or latent-firing nozzle. We brought in a tech who told us it was a known issue with those heads. They're not worth repairing or maintaining since there is a high likelihood the same issue will re-appear in a year. They do make nice racks for hanging large prints, however

Horace

Cleveland

Horace

Cleveland

I have 2 P9000 printers and I get some nozzle clogs in the winter when the humidity in my proofing dept. goes below 30%. We have a humidifier that we run 24 hrs a day in the winter and when the humidity is above 30% we have a lot less nozzle clogs. In the summer with the humidity running around 40% and above, we rarely have a nozzle clog. For the humidity to be effective in the winter the temperature should be above 65F. Unfortunately, That won't help the wiggle on each side, but should help with nozzle clog issues.I have been getting horizontal banding in my cyan when printing. First I thought it was due to a clogged inkjet, but after cleaning and testing I see that the light cyan has an alignment issue. Every jet is clean, but the edges of the light cyan test strip show that there is a wiggle on each side. I have done a number of alignment cycles, but that did not change it at all. When printing a file that has any solid blues, I get banding from this defect. Is this fixable? Does anyone have any suggestions?

Igor Kovalchuk

Member

MIKERANK you right temperature and humidity very important for stabiliyu work equipment but in this situation problem not only in this. Additional we have problem with Ink or print head if change Ink not solve problem next step recovery or change print head.

Similar threads

- Replies

- 1

- Views

- 338

- Replies

- 0

- Views

- 277

InSoft Automation

|

InSoft Automation Unveils Imp Version 14

Revolutionizing Layout Planning and Automation InSoft Automation announces the launch of Imp Version 14, the latest iteration of its industry-leading cost-based layout planning software. Packed with cutting-edge features, this release redefines efficiency, automation, and workflow optimization for printing and finishing processes. Learn more……. |