plotterraum

Member

Hi Guys,

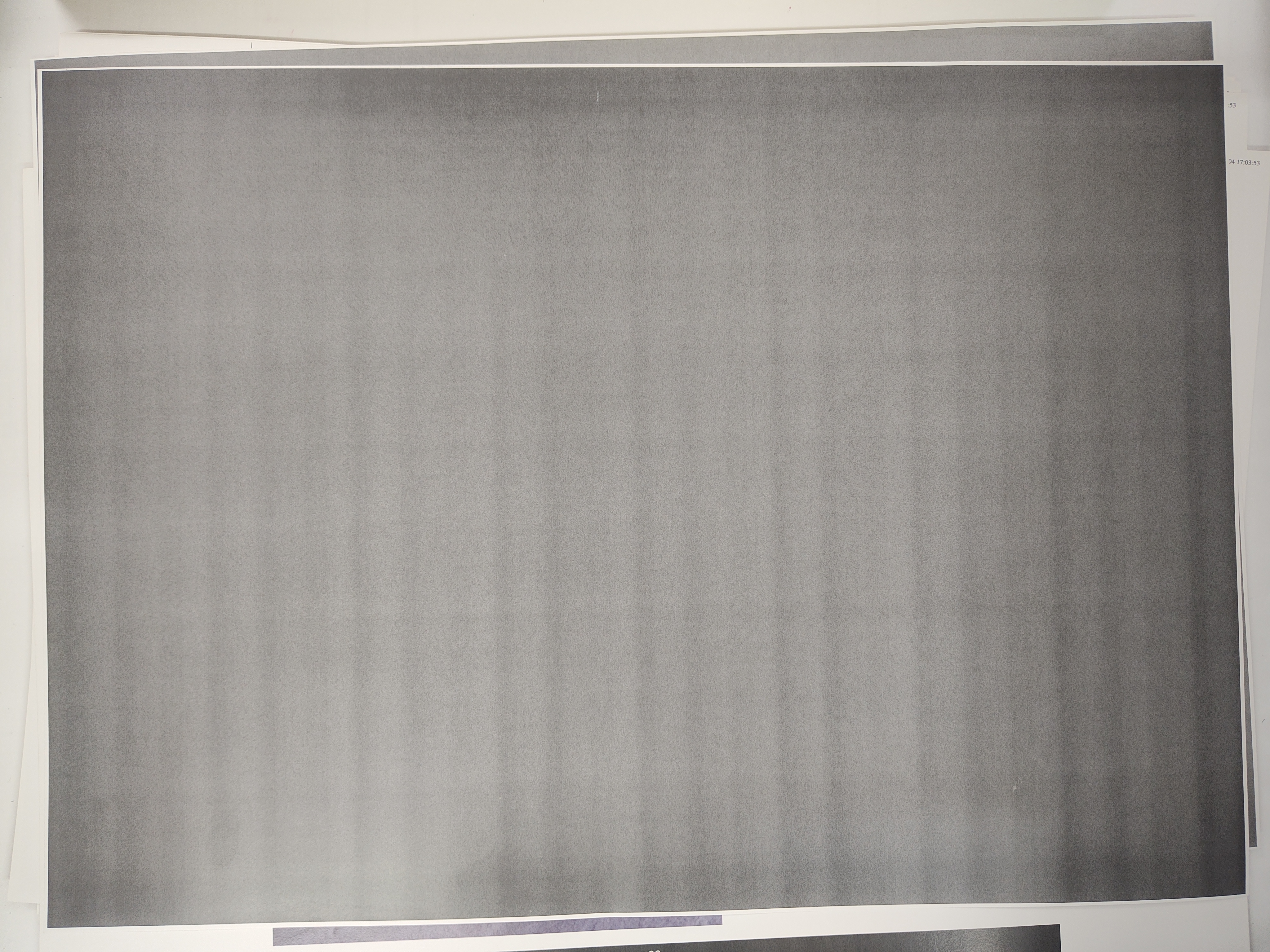

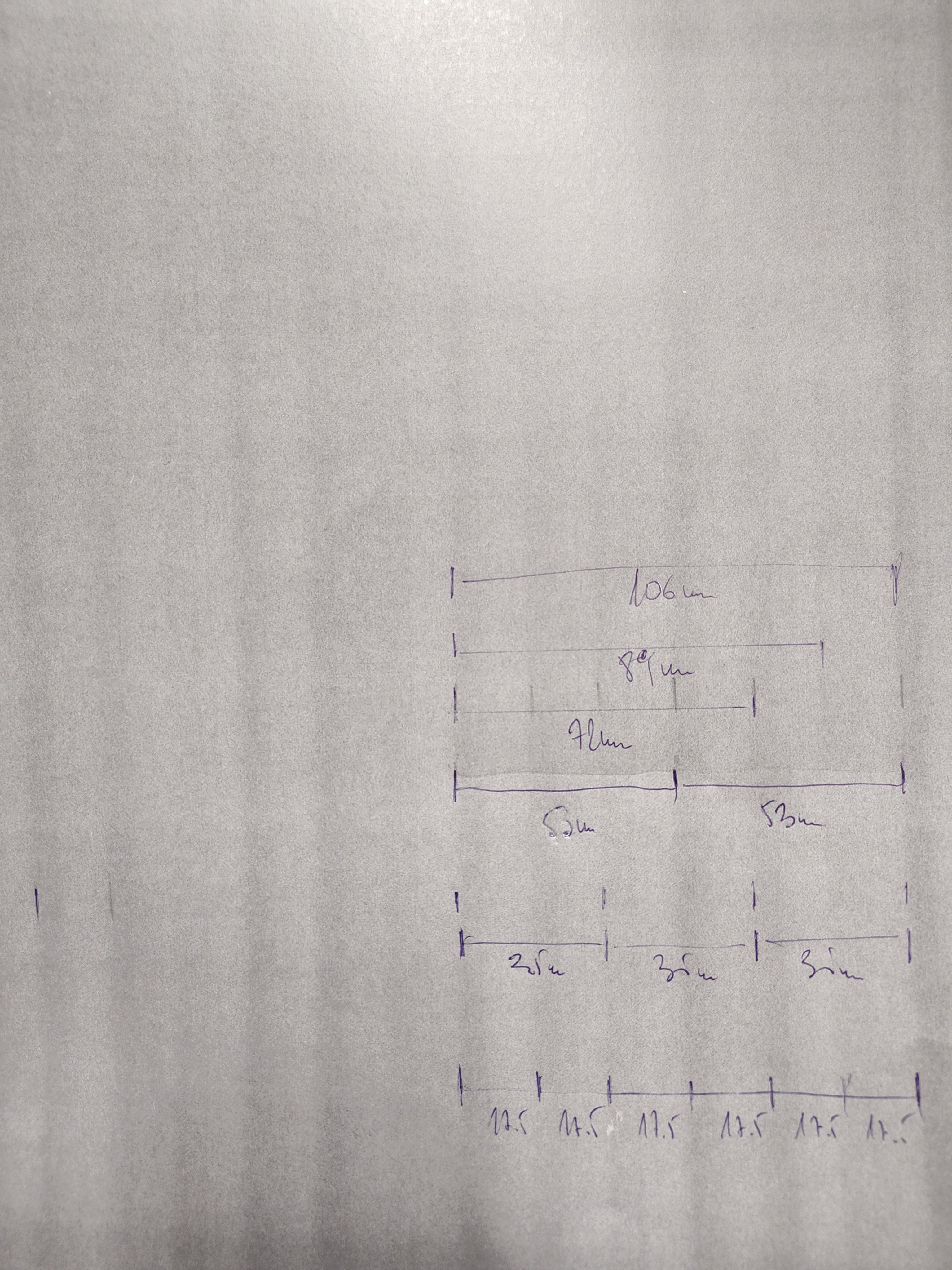

we have a used C7100x, - I have a banding pattern in Black, which I initialy believed, is could be developer related - 50mm, 25mm pattern. - but I am not sure anymore, ... I attach a foto.

A single pattern is ca. 17,5-18mm (ca. 0.7in) wide,

- two ca 35mm (1.38in),

- three ca. 53mm (2.09in),

- four ca. 89mm (3.50in), -

- five 106mm (4.17in) etc.

- I did not find any similar pattern listed in the service documentation (there is only the 62mm/2.4in and 189mm/7.5in pattern - and the already mentioned 50mm, 25mm - or 52mm, 25mm).

Other colors are all good.

I have access to the whole documentation, and already tried the steps mentioned for this issue (initialisation, toner refresh, DEMS - multiple times already), - to no avail. Charge Unit has also been exchanged, - I did not exchange the Cleaning Unit, but I doubt that could be the problem (?).

The machine has a pretty high milage - over 6 Million Pages (3 Mio in color plus 3 Mio BW). - has been used under Ricoh contract until under ca. 5 Mio., but after this - the previous owner just serviced what had to be done, - and probably did not try every possible option. -

Do you have any Idea / possible solution?

Thank you for any help!

we have a used C7100x, - I have a banding pattern in Black, which I initialy believed, is could be developer related - 50mm, 25mm pattern. - but I am not sure anymore, ... I attach a foto.

A single pattern is ca. 17,5-18mm (ca. 0.7in) wide,

- two ca 35mm (1.38in),

- three ca. 53mm (2.09in),

- four ca. 89mm (3.50in), -

- five 106mm (4.17in) etc.

- I did not find any similar pattern listed in the service documentation (there is only the 62mm/2.4in and 189mm/7.5in pattern - and the already mentioned 50mm, 25mm - or 52mm, 25mm).

Other colors are all good.

I have access to the whole documentation, and already tried the steps mentioned for this issue (initialisation, toner refresh, DEMS - multiple times already), - to no avail. Charge Unit has also been exchanged, - I did not exchange the Cleaning Unit, but I doubt that could be the problem (?).

The machine has a pretty high milage - over 6 Million Pages (3 Mio in color plus 3 Mio BW). - has been used under Ricoh contract until under ca. 5 Mio., but after this - the previous owner just serviced what had to be done, - and probably did not try every possible option. -

Do you have any Idea / possible solution?

Thank you for any help!