TroyHoover

Member

Hello,

We just had a Ricoh c9200 installed a few weeks ago and we are having a print quality issue that we cannot seem to fix. The techs from the company we purchased the machine from have never seen this issue before, besides on our old press(I will describe later) and have tried altering many paper settings to no avail. They are currently working on it with Ricoh so I'm sure they will be able to at least figure out what is causing it, but in the meantime I figured I'd post this here to see if anyone has had this print issue before.

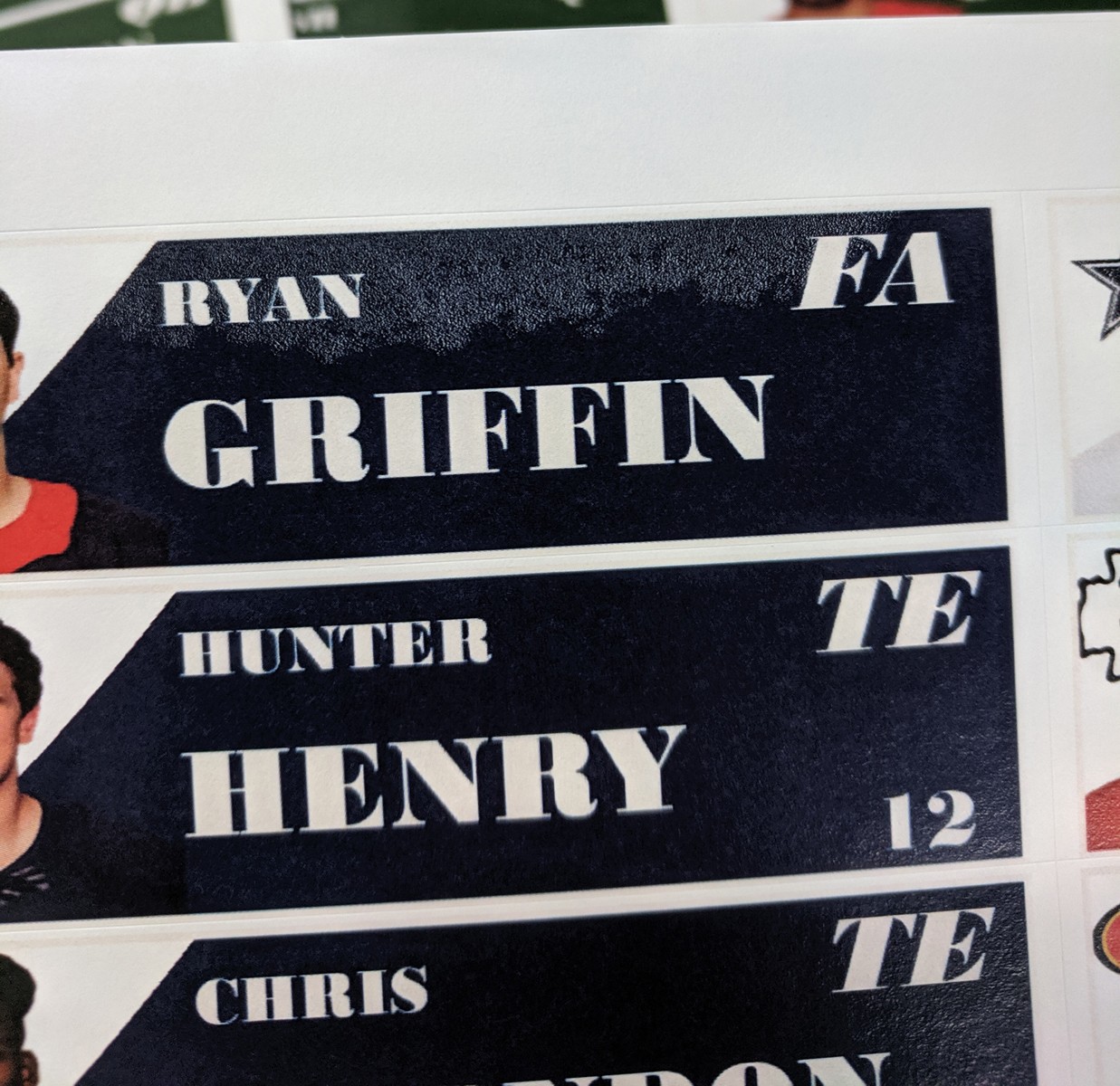

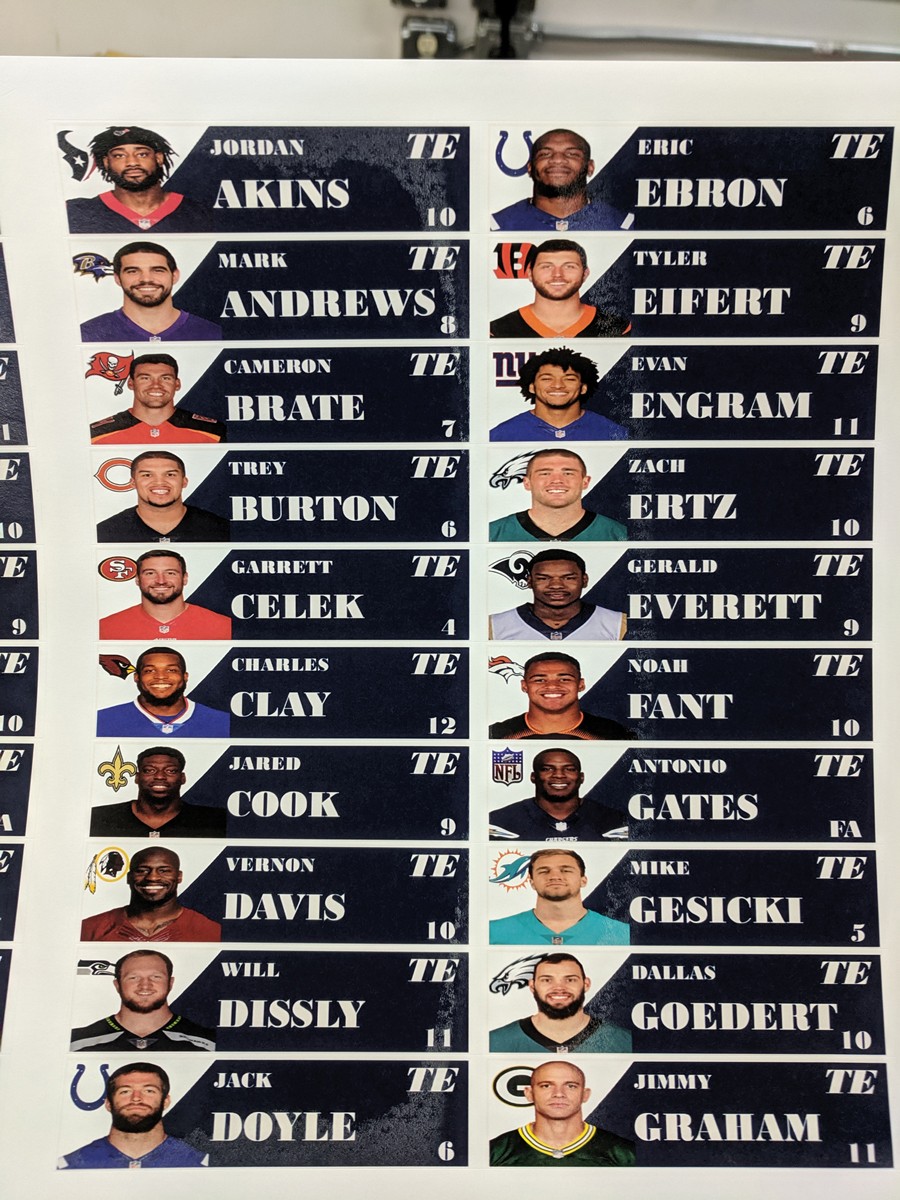

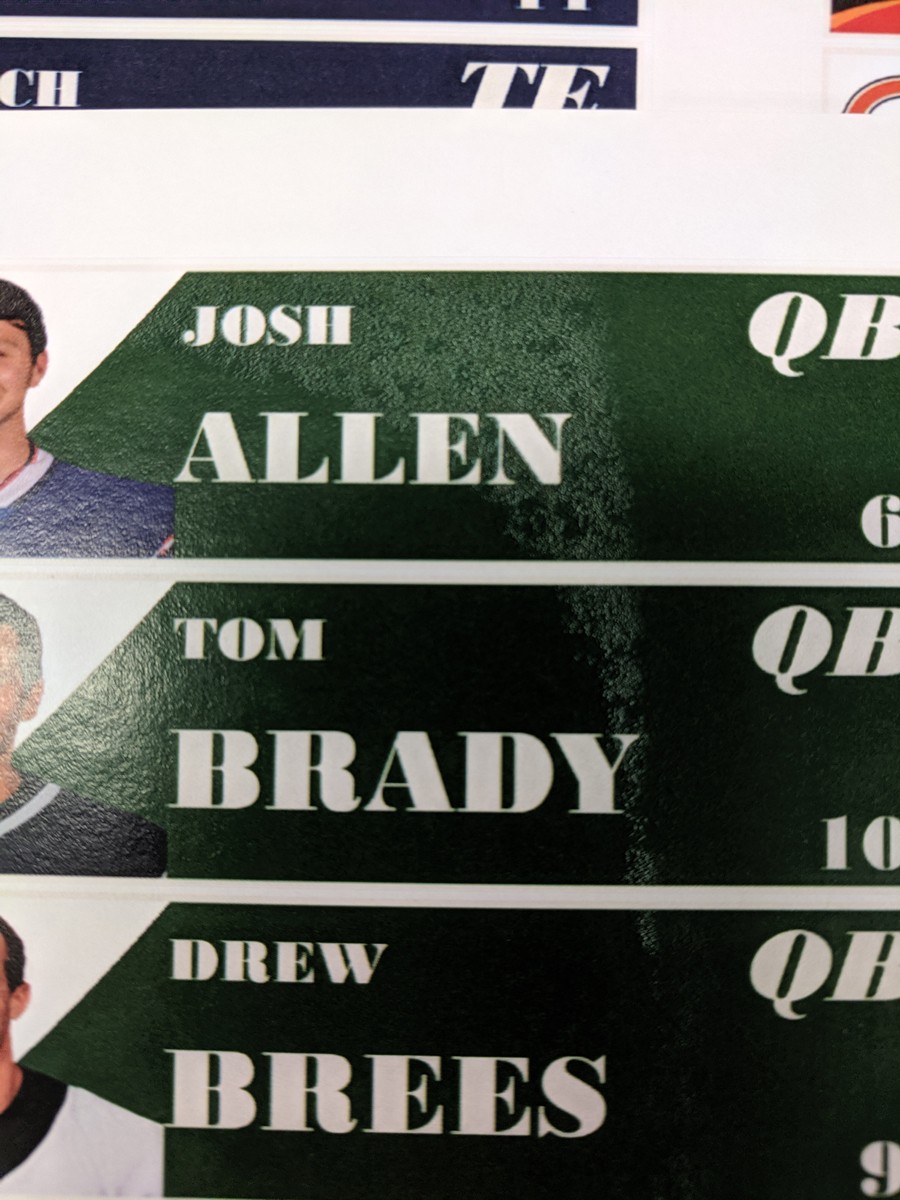

I would describe it as splotches of faded toner. I'm not sure exactly what the correct term for it is. The pictures I've attached show examples of it. IMG-01 is a full shot of an 11x17 sheet, the issue is present in the third column of players. The paper is being fed from the left side, where my hand is. IMG-02 is a close up of the issue when it is getting worse but before it grows enough to arc down the sheet. IMG-03 is a close up on the right side of an 11x17 sheet to show that sometimes it will happen twice on a sheet. IMG-04 is to show that it is happening on other colors.

It only shows up on 11 x 17 sheets and after the job has been running for a couple minutes, about 200 sheets in. It starts off very small at the top and bottom edges of the print, about 9 inches in from the lead edge. As the job continues to run, the spots grow and grow until they eventually create an arc across the page and connect. If I finish a stack of sheets and start printing more within 5 minutes, the issue will come back up within 50 sheets since the machine is already warmed up. Since it occurs when the machine is warmed up my first guess was that the fuser was getting too hot, but I tried changing the heat settings and the techs did as well but it did not help. I have the settings for the paper correctly entered, directly from the material spec sheets. I did try running at a thicker gsm than the paper actually is and it seemed to help a little but the problem still occurred. The issue does not appear when I print 8.5 x 11 so I can print at that size with no issues, but it is double the click charges. Fine for small jobs but not great for large jobs. My only other work-around so far is to print a couple hundred sheets, wait for the machine to sit for a little, print a couple hundred etc. The sheets we are printing on are die cut sheet labels. The techs and I tested the sheet label material with no die cuts whatsoever and it still happened, so it is not the die cuts causing it. I mentioned earlier that this had happened on our old press. Our old press is a Ricoh c900 this exact same issue would happen rarely on that press as well. The only difference is that it would only happen on our mid gloss and high gloss sheet labels and only on certain jobs. It seemed to happen mostly on jobs that had large areas of solid color in the artwork. The issue was never resolved because it would only pop up a handful of times a year. The c900 printed all of our other stocks with no issues. Now on the new press, the c9200, it is happening on all of our stocks, even our basic uncoated label stock. It is happening on all of the jobs as well no matter what the artwork is, even a black and white text job that I printed a few days ago. I went through the troubleshooting manual and tried the adjustments recommended for any print issue that was remotely close to what I am getting and none of them resolved the issue. I did not see a print issue described in the manual that accurately represented what is occurring on my prints.

Have any of you seen a similar print issue before? Did you find out what was causing it? Even if it isn't the same model or even a Ricoh, if you've seen something similar and found out what the cause was(e.g. heat, pressure, speed etc.), please let me know. Identifying what is causing the toner to appear like that is at least one step in the right direction, then I can move on to fixing it.

Thank you,

Troy

We just had a Ricoh c9200 installed a few weeks ago and we are having a print quality issue that we cannot seem to fix. The techs from the company we purchased the machine from have never seen this issue before, besides on our old press(I will describe later) and have tried altering many paper settings to no avail. They are currently working on it with Ricoh so I'm sure they will be able to at least figure out what is causing it, but in the meantime I figured I'd post this here to see if anyone has had this print issue before.

I would describe it as splotches of faded toner. I'm not sure exactly what the correct term for it is. The pictures I've attached show examples of it. IMG-01 is a full shot of an 11x17 sheet, the issue is present in the third column of players. The paper is being fed from the left side, where my hand is. IMG-02 is a close up of the issue when it is getting worse but before it grows enough to arc down the sheet. IMG-03 is a close up on the right side of an 11x17 sheet to show that sometimes it will happen twice on a sheet. IMG-04 is to show that it is happening on other colors.

It only shows up on 11 x 17 sheets and after the job has been running for a couple minutes, about 200 sheets in. It starts off very small at the top and bottom edges of the print, about 9 inches in from the lead edge. As the job continues to run, the spots grow and grow until they eventually create an arc across the page and connect. If I finish a stack of sheets and start printing more within 5 minutes, the issue will come back up within 50 sheets since the machine is already warmed up. Since it occurs when the machine is warmed up my first guess was that the fuser was getting too hot, but I tried changing the heat settings and the techs did as well but it did not help. I have the settings for the paper correctly entered, directly from the material spec sheets. I did try running at a thicker gsm than the paper actually is and it seemed to help a little but the problem still occurred. The issue does not appear when I print 8.5 x 11 so I can print at that size with no issues, but it is double the click charges. Fine for small jobs but not great for large jobs. My only other work-around so far is to print a couple hundred sheets, wait for the machine to sit for a little, print a couple hundred etc. The sheets we are printing on are die cut sheet labels. The techs and I tested the sheet label material with no die cuts whatsoever and it still happened, so it is not the die cuts causing it. I mentioned earlier that this had happened on our old press. Our old press is a Ricoh c900 this exact same issue would happen rarely on that press as well. The only difference is that it would only happen on our mid gloss and high gloss sheet labels and only on certain jobs. It seemed to happen mostly on jobs that had large areas of solid color in the artwork. The issue was never resolved because it would only pop up a handful of times a year. The c900 printed all of our other stocks with no issues. Now on the new press, the c9200, it is happening on all of our stocks, even our basic uncoated label stock. It is happening on all of the jobs as well no matter what the artwork is, even a black and white text job that I printed a few days ago. I went through the troubleshooting manual and tried the adjustments recommended for any print issue that was remotely close to what I am getting and none of them resolved the issue. I did not see a print issue described in the manual that accurately represented what is occurring on my prints.

Have any of you seen a similar print issue before? Did you find out what was causing it? Even if it isn't the same model or even a Ricoh, if you've seen something similar and found out what the cause was(e.g. heat, pressure, speed etc.), please let me know. Identifying what is causing the toner to appear like that is at least one step in the right direction, then I can move on to fixing it.

Thank you,

Troy

Last edited: