we just got a brand new press. after installation and calibration, we're about to do profiling. i find the tvi quite too low compared to standard value, is this perfectly alright for a new press. i attached some reading i got. please give suggestion or input. thanks...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

sheetfed tvi

- Thread starter ar17

- Start date

gordo

Well-known member

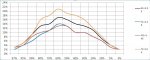

we just got a brand new press. after installation and calibration, we're about to do profiling. i find the tvi quite too low compared to standard value, is this perfectly alright for a new press. i attached some reading i got. please give suggestion or input. thanks...

What do you mean by "calibration"?

Also what do you mean by "about to do profiling" and why?

BTW, the TVI curves that you posted, if they come from plates with the same applied curves, suggest that your press is not in a proper printing condition.

best, gordo

sheetfed tvi

hi gordo.

when i say calibration. we run press optimization and set the machine to standard preset. we are supposed to do profiling of our existing papertypes but printing on a linear plate shows the tvi values as measured did not reached the prescribed tvi/dotgain as mentioned in iso12647-2. that's my question, is this perfectly natural or something is wrong. if things are wrong, what seems to be the things i should check. the tvi is from thermal plate with 150 lpi elliptical dot imaged as linear.

thanks for any input

ar

hi gordo.

when i say calibration. we run press optimization and set the machine to standard preset. we are supposed to do profiling of our existing papertypes but printing on a linear plate shows the tvi values as measured did not reached the prescribed tvi/dotgain as mentioned in iso12647-2. that's my question, is this perfectly natural or something is wrong. if things are wrong, what seems to be the things i should check. the tvi is from thermal plate with 150 lpi elliptical dot imaged as linear.

thanks for any input

ar

gordo

Well-known member

hi gordo.

when i say calibration. we run press optimization and set the machine to standard preset. we are supposed to do profiling of our existing papertypes but printing on a linear plate shows the tvi values as measured did not reached the prescribed tvi/dotgain as mentioned in iso12647-2. that's my question, is this perfectly natural or something is wrong. if things are wrong, what seems to be the things i should check. the tvi is from thermal plate with 150 lpi elliptical dot imaged as linear.

thanks for any input

ar

Well, whether the dot gain is high or low doesn't matter since that can be compensated for with a dot gain curve. So, that's not an issue.

The issue you should be concerned with is the shape of the curves. That is the problem.

If, for example, the plates are linear, then the TVI curves for each of the process colors should be almost the same. The only difference would be the total TVI caused by the difference in solid ink densities.

You can see that with the Black and Yellow press units. The shape of the curves are almost the same. That's good.

But the Cyan and Magenta have completely different shapes (even taking into account that the (low resolution) graph scales are different). They don't look like each other and neither curve looks like the Yellow and Black units.

To me, that suggests a problem with your Magenta and Cyan units.

I don't have enough info to know what the problem(s) is/are - but you should not be building curves or doing profiles until you figure out why the Cyan and Magenta curves don't look like the Yellow and Black TVI curves.

best, gordo

Last edited:

rich apollo

Well-known member

How many sheets did you measure? Gordo alluded to less than optimal conditions. Could be something in the printing of the particular sheet. Measure a number of sheets and average the measurements together to get a better idea of what the press is doing. This will smooth out specific spurious measurements and hiccups.

You can change how the press is printing in any of a number of ways. Increasing the pressure of the impression cylinder is the simplest. Change to a more compressible blanket. Change to a blanket with a different surface texture. A different paper will exhibit different behavior. Changes in the pH and conductivity of the fountain solution will alter your result. Turn down the water. Increase the speed of the ink fountain roller. Change the press speed and see if the ink transfer characteristics change. Increase the blanket and/or plate packing by a thousandth. Try an ink with a lower tack. Change the temperature of the fountain solution and/or the roller chillers (if the press has them).

I've observed presses printing with very low dot gain, so I don't consider what you're seeing unusual. View what you're doing, though, as profiling the characteristics of a system, not a press. You are documenting the physical and chemical interplay of a combination of ink, water, paper, blankets, pressures, temperatures, humidity, et cetera.

You can change how the press is printing in any of a number of ways. Increasing the pressure of the impression cylinder is the simplest. Change to a more compressible blanket. Change to a blanket with a different surface texture. A different paper will exhibit different behavior. Changes in the pH and conductivity of the fountain solution will alter your result. Turn down the water. Increase the speed of the ink fountain roller. Change the press speed and see if the ink transfer characteristics change. Increase the blanket and/or plate packing by a thousandth. Try an ink with a lower tack. Change the temperature of the fountain solution and/or the roller chillers (if the press has them).

I've observed presses printing with very low dot gain, so I don't consider what you're seeing unusual. View what you're doing, though, as profiling the characteristics of a system, not a press. You are documenting the physical and chemical interplay of a combination of ink, water, paper, blankets, pressures, temperatures, humidity, et cetera.

Disappointed

Well-known member

I have calibrated our waterless DI press many times, we don't use profiles. I can get iso12647 very easily now, what measurement devices/software are you using? What press is it?

All I do now is to linearise the press so 50% prints at 50% etc then I can throw any curve set at it I.e. Iso12647 and usually get a proof match immediately, we also use curves measured from other presses so we can print with similar results if required.

All I do now is to linearise the press so 50% prints at 50% etc then I can throw any curve set at it I.e. Iso12647 and usually get a proof match immediately, we also use curves measured from other presses so we can print with similar results if required.

Bloodsaler

Well-known member

gordo

Well-known member

The attachment is my brand new KBA Rapid 105 first test TVI.Problem in Yellow Unit,

But also why my tvi not smooth like the standard?

I check several samples,but not vary much like these shapes~

Have you applied any curves to the plates?

What halftone screening are you using?

How do the dots in the presswork look compared to the dots on the plates?

best, gordo

Last edited:

Bloodsaler

Well-known member

gordo

Well-known member

Not applied any curves to the plate.We use Euclidean 200 lpi~~

The attachment it the 50% area dot on the paper~

The ISO curves result from plates imaged using linear film - which is why they are symmetrical. Your curves don't look like that probably because your plates aren't linear. That's no problem.

Your black, cyan and yellow curves have a similar shape - which is good.

You need to find out why the Y has a higher TVI than the K even though it's running at a lower SID.

The Magenta curve is not far off from the C - which is good. The difference may result from measurement errors.

Dots/ink transfer look quite good.

Yes there is a problem with the Yellow - once that's figured out you could probably build plate curves to make you TVI curves look like the ISO ones.

best, gordo

Bloodsaler

Well-known member

Thanks gordo,I know there`s something wrong with Yellow unit,but my operator can`t find where is wrong,so I might ask for engineer`s help~

In all the fingerprint test,yellow always higher~

In all the fingerprint test,yellow always higher~

Similar threads

- Replies

- 1

- Views

- 546

- Replies

- 1

- Views

- 1231

- Replies

- 14

- Views

- 1427

PressWise

|

A 30-day Fix for Managed Chaos

As any print professional knows, printing can be managed chaos. Software that solves multiple problems and provides measurable and monetizable value has a direct impact on the bottom-line. “We reduced order entry costs by about 40%.” Significant savings in a shop that turns about 500 jobs a month. Learn how……. |