I do not know the design/layout.

If all the colors are used separately, you can of course try that. Please let us know after.

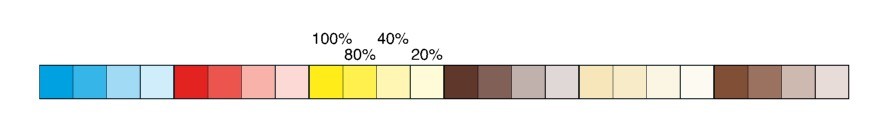

(However, I would have no confidence in the reproducibility of such a construct that may be based on six different dot gains for the same printing condition, although the similarity of four of these colors to the scale colors is so striking that they seemed are also intended to provide a "four-color" separation of a color image and such footage may have been converted to "CMYK", which in turn was assumed by identical dot gains via a “classic” profile like ISOcoatedv2 for cmy(k) ... But these are just guesses ...)

If I understand you correctly, you consider seriously to adapt the much more elaborate process (offset) with much more parameters are to controll to the result of a less elaborate process (digital proof).

That changes the direction: Normally the purpose of a proof is to simulate the more complex process (offset) ...

Completely outside you leave the density: Should all colors be printed with the same or those of CMYK correspondingly assigned and the light yellow with that of yellow and the brown with that of black or of cyan or magenta for reaching the optimum print contrast (I do not know the correct English term ...),?

Or is the best density that match the 100% patch visually nearest to the proof? (What could that mean to light and shadows?...)

For screened layouts is (maybe forgotten, but still important), in my humble opinion, to determine first the optimum print contrast. The ideal density for each color on a printed color series is to find regarding the result of screened patches (especially in lights and shadows) and printed with these densities leads you the respective dot gain for the single separation (for creating “normal” cmyk-profiles the average - c, m, y - dot gain is to determine, which is then the basis for the respective curve fittings in the RIP…).

I do not only know the design / layout, I can judge the claim of the customer only indirectly too (much want, less knowledge is a hint, that a might be high claim for e.g. a new brand on packaging is not developed by much experience...):

In short: I would communicate your necessary expenditure in any case to the customer and/or offer him a "low cost" alternative in treating the CMYK-like spot colors just like CMYK (unless it is about highly pigmented colors e.g. from Epple Anniva, then of course higher densities than usual / drive according to the manufacturer's specifications and previously convert to the profile from Epple/Anniva for that ...) and make a real print (offset on stock paper) with selected layouts from him and next step he has to correct his files, if necessary ...

But maybe your customer is happy with the result of your thought/stated method because he feels cared “enough”