You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which dot shape?

- Thread starter Dario

- Start date

SteveSuffRIT

Well-known member

The purpose of halftone screening is NOT to be noticed, at normal viewing distance (16") and substrate/process appropriate screen ruling frequency (150 lpi).

You only see the dot shape/structure under magnification, for troubleshooting and problem solving.

Any dot shape that forms a checkerboard pattern at 50% may have a sudden dot gain jump at mid-tones.

Round shape postpones mid-tone dot gain farther down tone scale (~>68%).

Elliptical is a compromise since 2 edges of dots touch/join at 50%.

You only see the dot shape/structure under magnification, for troubleshooting and problem solving.

Any dot shape that forms a checkerboard pattern at 50% may have a sudden dot gain jump at mid-tones.

Round shape postpones mid-tone dot gain farther down tone scale (~>68%).

Elliptical is a compromise since 2 edges of dots touch/join at 50%.

gordo

Well-known member

That study contains so many errors and is so poorly conducted that it should basically be ignored.

Here's basically why (I could go into more detail about the problems with this study but there's no point)

"The purpose of this study is to determine if significant improvements can be made in halftone reproduction by implementing an alternative screening (XM) method when compared to a conventional (AM) screening."

However, that's not what was actually tested.

What was actually tested was the impact of different halftone frequencies (lpi): 200lpi, 240lpi, and 340lpi since all the screens that were used were the same AM screen (Agfa Balanced AM Screening) except for the 1-2% and 98-99% dots. Those 1-2% and 98-99% dots would have effectively zero impact on the metrics/criteria that the author tested.

"the only conclusion that can be drawn from this research is there is a

measurable difference in the screening methods"

That's correct - however that is not what was tested in this study. So the conclusion is misleading at best and is also irrelevant.

Last edited:

gordo

Well-known member

In order from best to least:

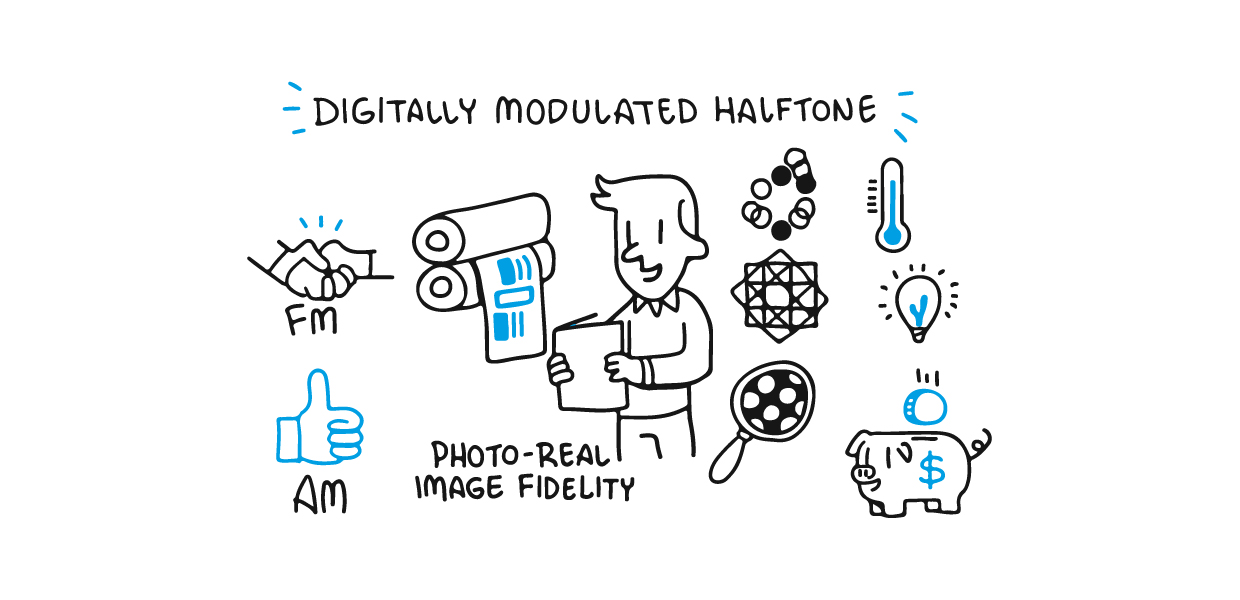

FM screening (second order/hybrid (especially DM a variant))

Of the AM screens it’s round dot AM - I.e. non transforming round through the tone scale.

For more detail:

AM dots: AM Screening Halftone Dot Shapes

FM dots: AM Screening Halftone Dot Shapes

XM: Hybrid AM Screening/XM Screening

FM screening (second order/hybrid (especially DM a variant))

Of the AM screens it’s round dot AM - I.e. non transforming round through the tone scale.

For more detail:

AM dots: AM Screening Halftone Dot Shapes

FM dots: AM Screening Halftone Dot Shapes

XM: Hybrid AM Screening/XM Screening

Dario

Well-known member

That study contains so many errors and is so poorly conducted that it should basically be ignored.

that's nice!

gordo

Well-known member

Please see my edit to the original post.that's nice!

Alois Senefelder

Well-known member

Gordo,

Thank you for the Clarification regarding the "Dissertation from Clemson Uni.

Regards, Alois

Thank you for the Clarification regarding the "Dissertation from Clemson Uni.

Regards, Alois

gordo

Well-known member

Gordo,

Thank you for the Clarification regarding the "Dissertation from Clemson Uni.

Regards, Alois

What's particularly irksome is that this study went through the whole process from concept to publication with no one at Clemson University questioning or stopping it. Pitiful.

gordo

Well-known member

From my experience as an operator, I prefer FM screening. It carries (a lot) more detail in halftone and process images so your oh so popular full color printing these days has never looked better. There’s also no chance of Moire or Rosette pattern, so in those regards, there’s nothing better.

Absolutely.

But for printing screened tints of solids, AM is superior because it lays down smoother and shows no grain.

That depends of the design of the FM screen. Some are grainy - others not.

And far as AM dot patterns go, I also like Euclidean better but Elliptical is very similar. Look at your shadows, midtones, and highlights for reference.

The good thing about the Euclidean is that the dot shape, except for 50% tint, is the same for all screen angles and frequencies. And the dot is non-directional so it is less affected by press problems. But it puts the optical bump where the dots first connect at the 50% midtone tint which puts it in the most important and visible image tones. It also has conflicting ink/water requirements through the tone scale - more water in the 50%-100% to keep those tones open and less water in the 1%-50% to avoid washing out those tones.

Elliptical moderates the optical bump by splitting it in two – when the dots first touch at the long width at the 40% tint and then again at the short width at 60%. But the dot shape varies at different screen angles which can cause single color moiré and uneven dot gain. At low lpi frequencies the “chaining” of the dots as two points touch can cause lines to appear as artifacts. The dots are directional which can cause problems on press when slur and doubling can cause strong tone and color shifts depending on the angle of orientation of the dots relative to the angle of the paper as it travels through the press.

Hybrid screening was developed to merge AM and FM screening together and in doing so tries to produce the best of both worlds. I’ve not actually printed too much of that in practice, so I can’t comment too much about it. But I have heard that just like other types of screening, it has its own issues as well.

Not quite right. Hybrid screening was developed to overcome resolution limitations in the imaging process (CtP, plates, press). It was originally developed for flexo printing where the plates have low resolution and can't hold the small highlight and shadow dots.

Last edited:

gordo

Well-known member

I don’t think that the Hybrid screening I was referring to that’s in use in offset today, has anything to do with Flexo. As far as I know it was specifically developed with offset in mind, and it actually does combine some elements of FM screening with AM screening (among others) to essentially provide the best of both. I can’t can’t comment on its performance, though, because I’ve not worked with it before. Here’s one brand that I’m aware of:

Auraia Digitally Modulated Screening DMS - Hamillroad Software Limited

Auraia DMS dramatically enhances quality, stability, and gamut, while delivering ink savings over conventional screening for offset / litho printing.www.hamillroad.com

Ah. I don’t think I’d class DM screening as a hybrid. Most people would associate hybrid screening with Agfa’s XM. There are similar screening technologies from other vendors. Those were originally developed for flexo and were subsequently applied to offset for the same reason.

I have tried Round, Square, Euclidean in AM screening and printed a few jobs using FM, but have settled on Elliptical with 7.5° shifted angles as our standard.

Also had good results with FM screening for C,M & Y and AM on the black, it appears to give a sharper appearance.

I haven't used that technique since the Brisque days, and of course the FM screening has evolved since then.

Also had good results with FM screening for C,M & Y and AM on the black, it appears to give a sharper appearance.

I haven't used that technique since the Brisque days, and of course the FM screening has evolved since then.

DeltaE

Well-known member

Hi Magnus,I have tried Round, Square, Euclidean in AM screening and printed a few jobs using FM, but have settled on Elliptical with 7.5° shifted angles as our standard.

Also had good results with FM screening for C,M & Y and AM on the black, it appears to give a sharper appearance.

I haven't used that technique since the Brisque days, and of course the FM screening has evolved since then.

It sounds interesting with combination FM-C M Y and AM-K. Beside the better appearance, how do you think about the stability of color, especially gray tone (ex: CMYK = 50 40 40 15)

DeltaE

Well-known member

@gordoAh. I don’t think I’d class DM screening as a hybrid. Most people would associate hybrid screening with Agfa’s XM. There are similar screening technologies from other vendors. Those were originally developed for flexo and were subsequently applied to offset for the same reason.

Could you please share your idea about this screening DM? what is its disadvantage?

Do we need good consumables, good blankets... to print it on an offset machine?

Thanks in advance!

gordo

Well-known member

@gordo

Could you please share your idea about this screening DM? what is its disadvantage?

Do we need good consumables, good blankets... to print it on an offset machine?

Thanks in advance!

In my creo/kodak days I was surprised to see that quite a few Latin America publications printers (heatset web) were using FM for CMY and AM screening for K. The AM screened K has a lower lpi than the FM - this is normal. As a result, running the K as a relatively coarse AM screen gives a sharper/contrastier appearance to the image compared to running CMYK all FM or all AM.

In addition to general commercial offset, literally billions of magazine pages are printed annually using Hamillroad's Auraia DM screening on presses that are probably not in perfect condition. I don't want to spam the forum - so just go to their website for more info and samples.

Home - Hamillroad Software Limited

Experts in Digitally Modulated Screening (DMS) and prepress solutions for the printing industry. Our portfolio includes Bellissima DMS for flexographic printing and Auraia DMS for offset / lithographic printing.

www.hamillroad.com

Last edited:

Dario

Well-known member

For more detail:

AM dots: AM Screening Halftone Dot Shapes

FM dots: AM Screening Halftone Dot Shapes

XM: Hybrid AM Screening/XM Screening

That's the answer I wanted!!

@gordo thank you for the other pearls of wisdom: you are such a source of knowledge!!

Last edited:

DeltaE, none of the books we printed using this method had any flat tints, we always found FM to be too grainy for those jobs, we would pick & choose which jobs to print this way, most were books with blocks of mainly black text with photographs, so i couldn't really comment on the stability of 4 colour neutral greys or other flat tints.Hi Magnus,

It sounds interesting with combination FM-C M Y and AM-K. Beside the better appearance, how do you think about the stability of color, especially gray tone (ex: CMYK = 50 40 40 15)

I see Gordo elaborated on this method in another reply.

If I remember correctly, I originally got this idea from the old NNTP Usenet "Comp.Publish.Prepress" Newsgroup which was a great source of information in its day

Similar threads

- Replies

- 2

- Views

- 384

- Replies

- 0

- Views

- 298

- Replies

- 2

- Views

- 555

InSoft Automation

|

InSoft Automation Unveils Imp Version 14

Revolutionizing Layout Planning and Automation InSoft Automation announces the launch of Imp Version 14, the latest iteration of its industry-leading cost-based layout planning software. Packed with cutting-edge features, this release redefines efficiency, automation, and workflow optimization for printing and finishing processes. Learn more……. |