HillviewDPM

New member

Hello All,

I have a 1997 Challenge 305 CRT. I am having a few issues with it. We lost power last week for about 12 hours. But the cutter wasn't in use at the time of power loss, so I don't know if that could have caused the issues. I have shut it completely down and turned it back on, it did not solve the problems.

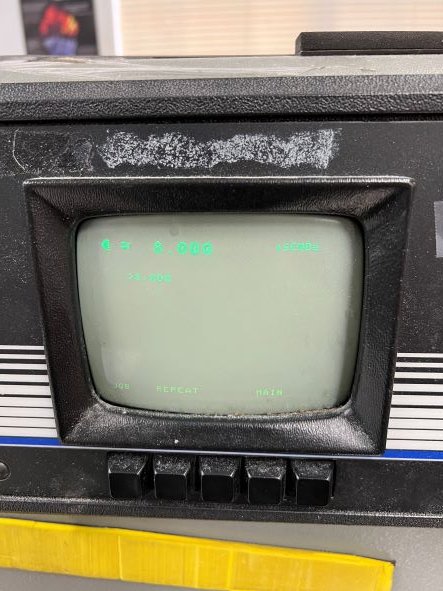

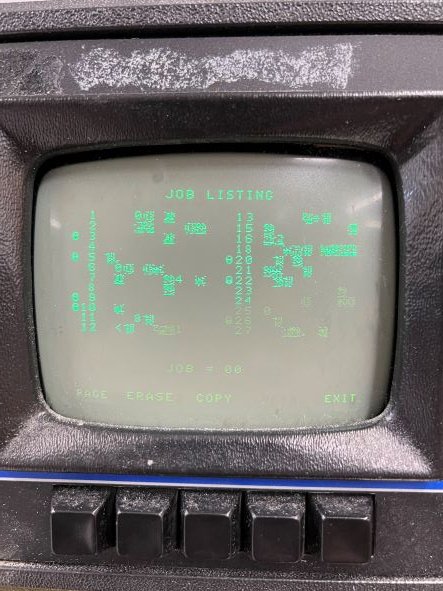

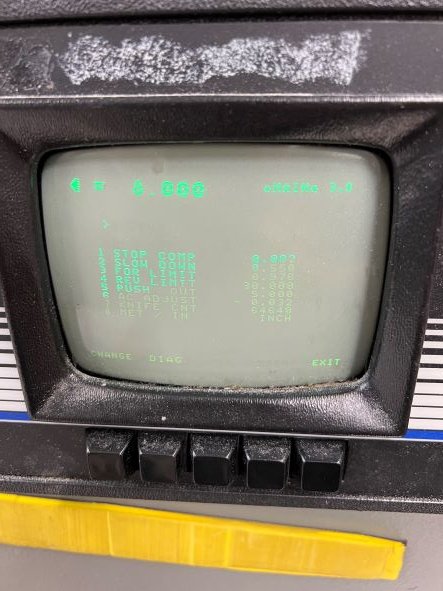

Problem 1: The screen seems completely normal, but when I go to the job list, it shows up as a jumbled mess. (Photos included.)

Problem 2: The back gauge moves slow for the majority of send mode going forward. For example; the back gauge is at 28.00in and I want to go to 5.00in. I type 5 and hit send. It moves fast from 28.0in to about 21.7in, then goes slow from 21.7in all the way to 5.0in. If I go reverse, so I'm at 5.0in and want to go to 27.0in. I type 27 and hit send. It goes fast from 5.0in to 28.0in, then goes slowly from 28.0in to 27.0in. If I use the the forward or reverse keys it will move fast in both directions and slow in both directions when I use the slow key.

Does anyone have any ideas...

I have a 1997 Challenge 305 CRT. I am having a few issues with it. We lost power last week for about 12 hours. But the cutter wasn't in use at the time of power loss, so I don't know if that could have caused the issues. I have shut it completely down and turned it back on, it did not solve the problems.

Problem 1: The screen seems completely normal, but when I go to the job list, it shows up as a jumbled mess. (Photos included.)

Problem 2: The back gauge moves slow for the majority of send mode going forward. For example; the back gauge is at 28.00in and I want to go to 5.00in. I type 5 and hit send. It moves fast from 28.0in to about 21.7in, then goes slow from 21.7in all the way to 5.0in. If I go reverse, so I'm at 5.0in and want to go to 27.0in. I type 27 and hit send. It goes fast from 5.0in to 28.0in, then goes slowly from 28.0in to 27.0in. If I use the the forward or reverse keys it will move fast in both directions and slow in both directions when I use the slow key.

Does anyone have any ideas...