Hello,

I have a cut-sheet digital press (toner) that is driven by a Fiery DFE. I recently acquired a i1 Pro 1 spectrophotometer and ever since I have been doing research in how to establish a proper workflow and how to do proper color management. Our workflow is as follows:

Say we want to print on something like this: GardaMatt Art

• We design whatever it is to be printed in CorelDRAW in CMYK.

• The CMYK ICC profile that we will use is ISO Coated v2, since we will be printing on a coated stock.

• The file is then exported to a PDF/X-3 .pdf file (we have an older version of CorelDRAW licenced that doesn't support X-4) with the CMYK color profile embedded to the file, which is then loaded on to the Fiery

Question #1: Say the client sends us some object that is in RGB rather than CMYK (basically every other day) and has to be included in the file. Should we let CorelDRAW do the conversion to CMYK during the export process, or should we let the Fiery handle the conversion from RGB to CMYK? For spot colors, for example, it is best to define it in CorelDRAW as a spot color, export the .pdf with the "Native" option enabled so that no cnversion to CMYK happens and then finally let the Fiery do the conversion to CMYK, so long as the Fiery has that particular spot color in its spot color library and all the correct RIP settings were used.

• After loading the job on the Fiery, we obviously have to pick the correct settings for the job. Which leads us to:

Question #2: Under "Expert Settings" in the "Color" tab, does the CMYK source profile have to match the same profile that is embedded on the .pdf file that we created previously? Finally, if we were to include a RGB object that has a ICC profile attached to it and the RGB values weren't converted to CMYK during the .pdf export process, should the RGB source profile on the Fiery also have to match that profile that was embedded to the RGB object?

Also, how can I make sure that my digital press, when printing with coated media that we used basically 90% of the time (which probably has enough gamut for the job), can reproduce all the colors specified in a profile like ISO Coated v2?

Would calibrating the press to G7 targeted help with this? I have Fiery Color Profiler Suite v4.9.0.21 installed on my computer - we of course calibrate with the calibration wizard from CWS for the paper that we print on).

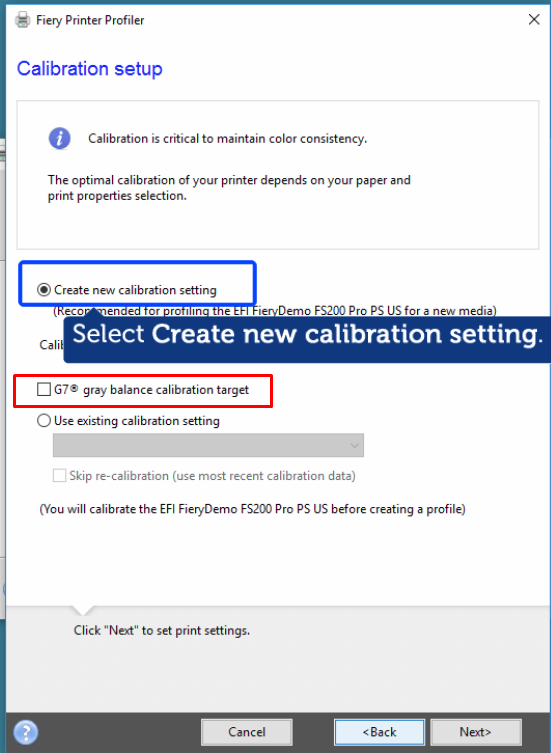

Finally, a technical question for anyone that has done G7 on the FCPS before - does anyone know why the checkbox I outlined (in red) would be greyed out?

Thanks in advance to anyone who chimes in - hope my questions aren't completely daft!

I have a cut-sheet digital press (toner) that is driven by a Fiery DFE. I recently acquired a i1 Pro 1 spectrophotometer and ever since I have been doing research in how to establish a proper workflow and how to do proper color management. Our workflow is as follows:

Say we want to print on something like this: GardaMatt Art

• We design whatever it is to be printed in CorelDRAW in CMYK.

• The CMYK ICC profile that we will use is ISO Coated v2, since we will be printing on a coated stock.

• The file is then exported to a PDF/X-3 .pdf file (we have an older version of CorelDRAW licenced that doesn't support X-4) with the CMYK color profile embedded to the file, which is then loaded on to the Fiery

Question #1: Say the client sends us some object that is in RGB rather than CMYK (basically every other day) and has to be included in the file. Should we let CorelDRAW do the conversion to CMYK during the export process, or should we let the Fiery handle the conversion from RGB to CMYK? For spot colors, for example, it is best to define it in CorelDRAW as a spot color, export the .pdf with the "Native" option enabled so that no cnversion to CMYK happens and then finally let the Fiery do the conversion to CMYK, so long as the Fiery has that particular spot color in its spot color library and all the correct RIP settings were used.

• After loading the job on the Fiery, we obviously have to pick the correct settings for the job. Which leads us to:

Question #2: Under "Expert Settings" in the "Color" tab, does the CMYK source profile have to match the same profile that is embedded on the .pdf file that we created previously? Finally, if we were to include a RGB object that has a ICC profile attached to it and the RGB values weren't converted to CMYK during the .pdf export process, should the RGB source profile on the Fiery also have to match that profile that was embedded to the RGB object?

Also, how can I make sure that my digital press, when printing with coated media that we used basically 90% of the time (which probably has enough gamut for the job), can reproduce all the colors specified in a profile like ISO Coated v2?

Would calibrating the press to G7 targeted help with this? I have Fiery Color Profiler Suite v4.9.0.21 installed on my computer - we of course calibrate with the calibration wizard from CWS for the paper that we print on).

Finally, a technical question for anyone that has done G7 on the FCPS before - does anyone know why the checkbox I outlined (in red) would be greyed out?

Thanks in advance to anyone who chimes in - hope my questions aren't completely daft!