Hello, plq i need your help

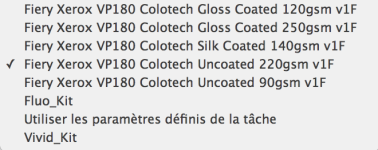

I have a v180 when i print in 90gms uncoated or 170g coated paper the colors printing are good but when i print the same file in 300g coated or adhesive sticker the color is too light a big difference i tried to make calibaration with spectromètre fs 2000 but no result, is a calibration issue, pls what the best way to make calibration ?

Also i have aproblem with magenta the right edge is little dark to the left edge i have make density uniformity but the same result, it can be a drum problems ?

The machine is in 1millions prints

Thank you

I have a v180 when i print in 90gms uncoated or 170g coated paper the colors printing are good but when i print the same file in 300g coated or adhesive sticker the color is too light a big difference i tried to make calibaration with spectromètre fs 2000 but no result, is a calibration issue, pls what the best way to make calibration ?

Also i have aproblem with magenta the right edge is little dark to the left edge i have make density uniformity but the same result, it can be a drum problems ?

The machine is in 1millions prints

Thank you