I am trying to get my shop to on some sort of standard, so that when we print jobs, they come out matching our proofer, and can be matched again.

We have two offset 4 color presses a heidelberg 5 color and presstek DI, and a offset 2 color press, along with a couple small 2 color offsets for one up cards etc. We have a platesetter (Heidelberg topsetter) outputting to all the press's except the presstek DI press, which gets 1bit tiffs sent from navigator to DI tools, then to the press.

We recently upgraded the rip to Xitron Navigator 8.1 , and am trying to figure out the best way of achieving some sort of calibration. Xitron sells ColorPro, which makes profiles automatically but is pretty expensive, so I am trying to make do with what we have, an Eye1 pro, Xrite-408 (can read dot % ), and profilemaker5.

After talking to the xitron tech, he recommended leaving the rip uncalibrated and making icc profiles for each press and preflight with that profile, allowing the rip to manage icc profile in the pdf. We could make these with the Eye1 & Profilemaker5

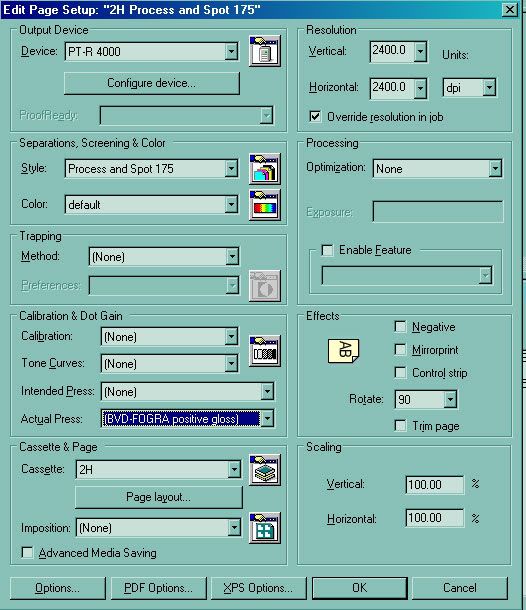

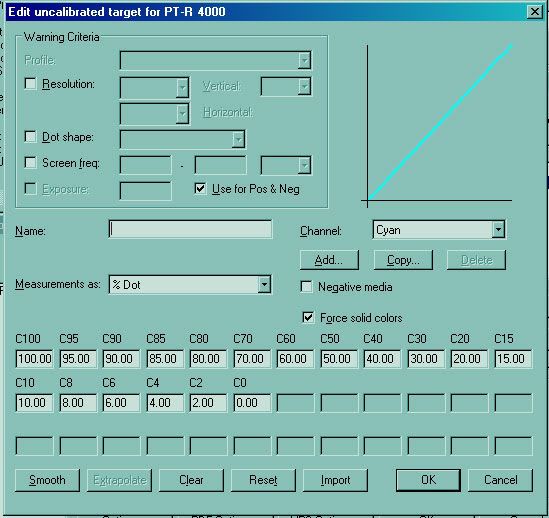

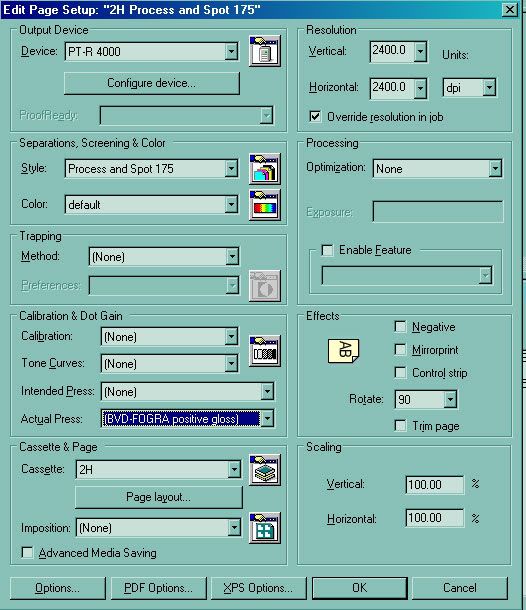

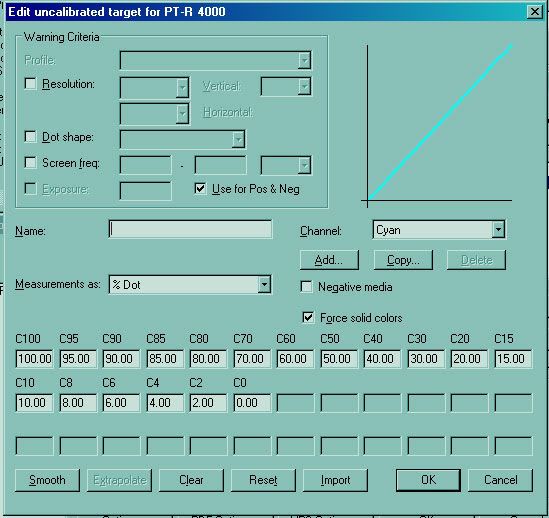

Alternatively I could use a densitometer ( Xrite 408 ) to set the actual press curves (screenshot below) and fingerprint each press, and match them to one standard.

I am leaning towards fingerprinting, and am unsure which standard I should try to achieve. I like the idea of the G7, but might be too complex for our shop workflow. I used the Gracol 2006 v2 profile in pitstop and it seems to be pretty achievable now.

Would this be a good way to go or should I just attach the press profile in pitstop and send out to the rip with no other corrections applied?

I am trying to finish up Real World Color Management, and have found it to be a good resource, but you guys sure know your stuff!!

[br]

We have two offset 4 color presses a heidelberg 5 color and presstek DI, and a offset 2 color press, along with a couple small 2 color offsets for one up cards etc. We have a platesetter (Heidelberg topsetter) outputting to all the press's except the presstek DI press, which gets 1bit tiffs sent from navigator to DI tools, then to the press.

We recently upgraded the rip to Xitron Navigator 8.1 , and am trying to figure out the best way of achieving some sort of calibration. Xitron sells ColorPro, which makes profiles automatically but is pretty expensive, so I am trying to make do with what we have, an Eye1 pro, Xrite-408 (can read dot % ), and profilemaker5.

After talking to the xitron tech, he recommended leaving the rip uncalibrated and making icc profiles for each press and preflight with that profile, allowing the rip to manage icc profile in the pdf. We could make these with the Eye1 & Profilemaker5

Alternatively I could use a densitometer ( Xrite 408 ) to set the actual press curves (screenshot below) and fingerprint each press, and match them to one standard.

I am leaning towards fingerprinting, and am unsure which standard I should try to achieve. I like the idea of the G7, but might be too complex for our shop workflow. I used the Gracol 2006 v2 profile in pitstop and it seems to be pretty achievable now.

Would this be a good way to go or should I just attach the press profile in pitstop and send out to the rip with no other corrections applied?

I am trying to finish up Real World Color Management, and have found it to be a good resource, but you guys sure know your stuff!!

[br]

Last edited: