Using 3.2.2.171 of the Kodak Proofing software, to Epson printers. Hot folders used to be visible, however after a restart, I get an error message (repeated in the screen grab below). Does anyone know how to resolve this?

Configure -> Hot folders/ Virtual Printers:

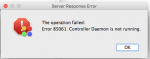

'The operation failed: Error 85061: Controller Daemon is not running'

in the Kodak Proofer Administrator, window, all software seems to be running.

Configure -> Hot folders/ Virtual Printers:

'The operation failed: Error 85061: Controller Daemon is not running'

in the Kodak Proofer Administrator, window, all software seems to be running.