thermoprinter

Member

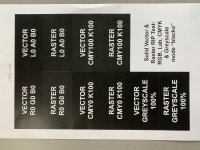

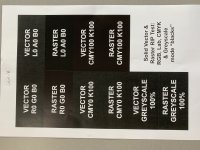

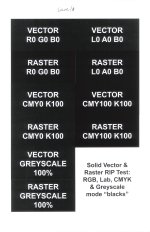

I've owned my Ricoh 9100 machine for about 3 years now. Since owning it I've had a major issue printing black ink. When I run a grayscale print job, the black comes out very light. I have to make several adjustments just to get the black to come out clearly - like changing print profiles or adjusting the darkness of prints. Also, when I print files with any percentage of black (40/50/60/70% black - basically any screen of black), the print comes out extemely light and sometimes unreadable. This happens when I print in grayscale or in color. So if a color document has text that is 50% black, the print would be hard to read. This issue isn't only on text but also on solid grays (any percentage of black). On solid grays, the solid part would be very blotchy and would not print out solid.

I have many different Ricoh techs and color specialists look at this but none of them have a solution. They have rebuilt profiles and provided a bunch of adjustments but nothing that works consistently. As far as I can tell, this is a common issue on the Ricoh 9100 boxes. Ricoh has pretty much swept this issue under the rug without actually admitting this is a known issue.

I'm just wondering if anyone else has experienced this and if they've found a solution.

I have many different Ricoh techs and color specialists look at this but none of them have a solution. They have rebuilt profiles and provided a bunch of adjustments but nothing that works consistently. As far as I can tell, this is a common issue on the Ricoh 9100 boxes. Ricoh has pretty much swept this issue under the rug without actually admitting this is a known issue.

I'm just wondering if anyone else has experienced this and if they've found a solution.